Why Adding UV Stabiliser into BOPP Films for Outdoor Graphics Applications?

Introduction to Outdoor Graphic Requirements

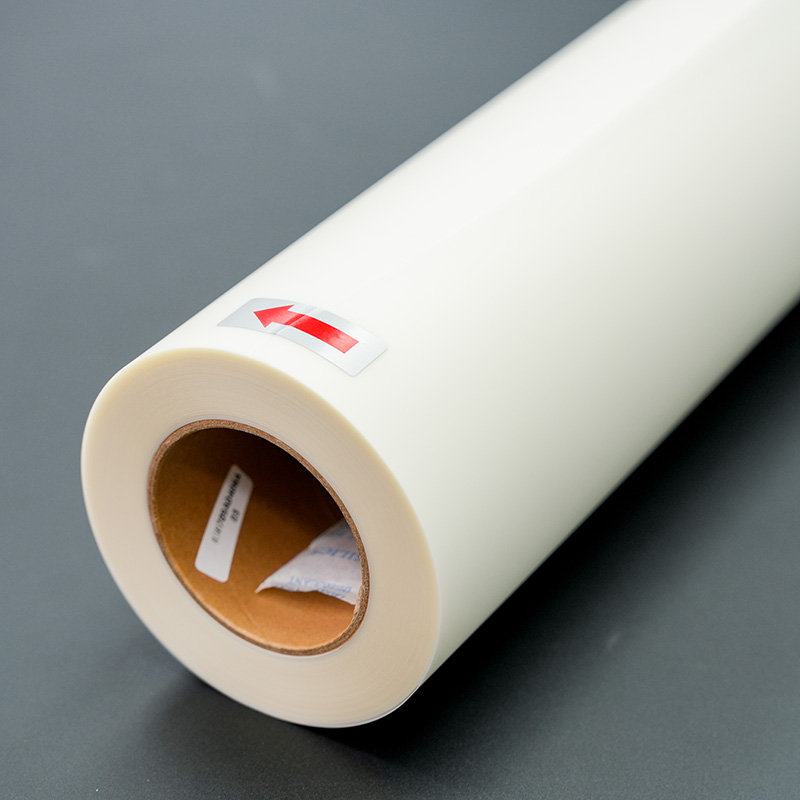

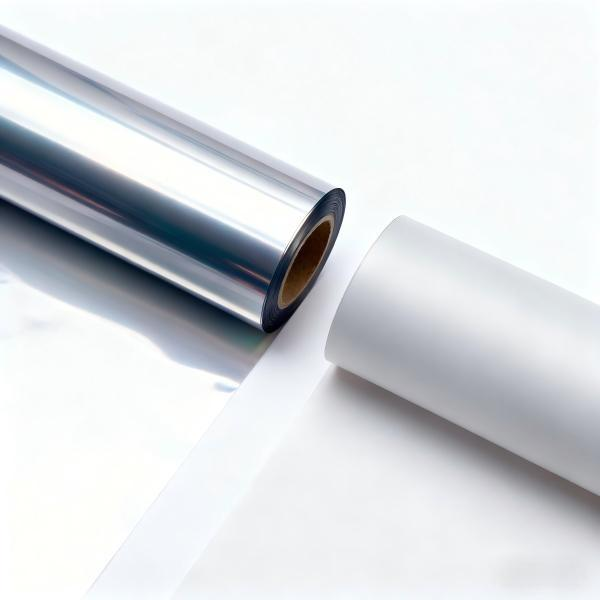

Outdoor graphic materials face constant exposure to sunlight, heat, moisture, and environmental stress. To meet these challenges, BOPP films for outdoor graphics applications must deliver long-term durability, color stability, and mechanical strength. Adding UV stabiliser into substrate BOPP film is a critical modification that significantly improves performance. For converters and printers working with BOPP films for graphic industry, UV protection is no longer optional but essential.

The Role of UV Stabiliser in Substrate BOPP Film

Ultraviolet radiation can degrade polypropylene over time, leading to brittleness, discoloration, and loss of mechanical integrity. When UV stabiliser is incorporated into substrate BOPP film, it acts as a protective shield that absorbs or neutralizes harmful UV rays. This protection helps BOPP films for outdoor graphics applications maintain flexibility, strength, and visual quality during prolonged outdoor use. For manufacturers supplying BOPP films for graphic industry, UV-stabilized substrate ensures consistent performance across varying climates.

Enhanced Color and Print Durability

One of the primary benefits of UV stabiliser is improved print longevity. Outdoor graphics demand sharp images and vibrant colors that do not fade quickly. BOPP films for outdoor graphics applications with UV stabiliser help protect printed inks from fading and yellowing. This is especially important for BOPP films for HP Indigo printing, where color accuracy and image consistency are critical. By stabilizing the substrate BOPP film, UV additives ensure that printed graphics remain visually appealing over extended display periods.

Performance Benefits for the Graphic Industry

For the BOPP films for graphic industry, UV stabiliser enhances not only appearance but also functional reliability. UV-stabilized substrate BOPP film resists cracking, curling, and surface degradation, which are common problems in outdoor signage and promotional displays. These improvements reduce replacement frequency and improve overall cost efficiency for brand owners. As a result, BOPP films for outdoor graphics applications with UV stabiliser are widely recommended for banners, window graphics, posters, and outdoor labels.

Compatibility with HP Indigo Printing Technology

Digital printing technologies demand stable and consistent substrates. BOPP films for HP Indigo printing must withstand both the printing process and long-term outdoor exposure. Adding UV stabiliser to substrate BOPP film enhances thermal stability and surface integrity, supporting high-quality digital printing results. This compatibility ensures that BOPP films for HP Indigo printing perform reliably in demanding graphic applications without compromising print resolution or adhesion.

Conclusion

Adding UV stabiliser into substrate BOPP film is a strategic enhancement for producing high-performance BOPP films for outdoor graphics applications. It improves durability, color retention, and structural stability while meeting the evolving needs of the BOPP films for graphic industry. Whether used in traditional signage or BOPP films for HP Indigo printing, UV-stabilized BOPP films deliver long-lasting quality and dependable performance in outdoor environments.

News & Events

learn more-

Blog

Press Release Dec-18-2025

Blog

Press Release Dec-18-2025How to Convert Substrate BOPP Film Into Label Facestock

The process of converting substrate BOPP film into BOPP film for label facestock involves several controlled steps that ensure excellent performance, adhesion, printability, and converting efficiency. -

Blog

Press Release Dec-18-2025

Blog

Press Release Dec-18-2025Top 10 China Suppliers of Substrate BOPP Films (2025)

China is one of the world’s largest producers of BOPP Film, supplying high-quality substrate BOPP films to packaging, printing, and lamination industries worldwide. With advanced production technology, large-scale manufacturing capacity, and competitive pricing, Chinese BOPP Film suppliers have become preferred partners for global buyers. -

Blog

Press Release Dec-18-2025

Blog

Press Release Dec-18-2025The Types of BOPP Films for Flexible Package Industry

BOPP films, or biaxially oriented polypropylene films, are essential materials widely used in the flexible packaging industry. Known for their clarity, strength, barrier properties, and suitability for printing and lamination, BOPP films support a broad range of applications across food, consumer goods, and industrial packaging. As packaging performance requirements continue to rise, different types of BOPP films have been developed to meet specific functional and aesthetic needs throughout the supply chain.

contact us

contact

Tel: +86 17706217416

Add: Building L2A, No. 520, Lane 1588, Zhuguang Road, Hongqiao World Center, Qingpu District, Shanghai, China