What is DTF

Introduction

In the dynamic world of fabric printing, the quest for techniques that offer both versatility and high - quality results is unending. Have you ever wondered how those intricate, long - lasting designs on your favorite T - shirts, tote bags, or home textiles are created? Enter DTF (Direct - to - Film) printing and its premium counterpart, DTF printing. These methods have revolutionized the fabric printing landscape, offering a range of benefits that set them apart from traditional printing techniques. Whether you're a fashion brand looking to create unique apparel, a small business aiming to produce custom - branded merchandise, or simply a fabric printing enthusiast, understanding DTF and DTF printing is crucial. In this blog post, we'll take a deep dive into what DTF printing is, how it works, and what makes DTF a game - changer in the industry.

What is DTF Printing?

DTF, or Direct - to - Film printing, has emerged as a popular and innovative method in the fabric printing industry. At its core, DTF printing is a digital textile printing technique that allows for the creation of high - quality, full - color designs on a wide variety of fabrics.

Materials Used

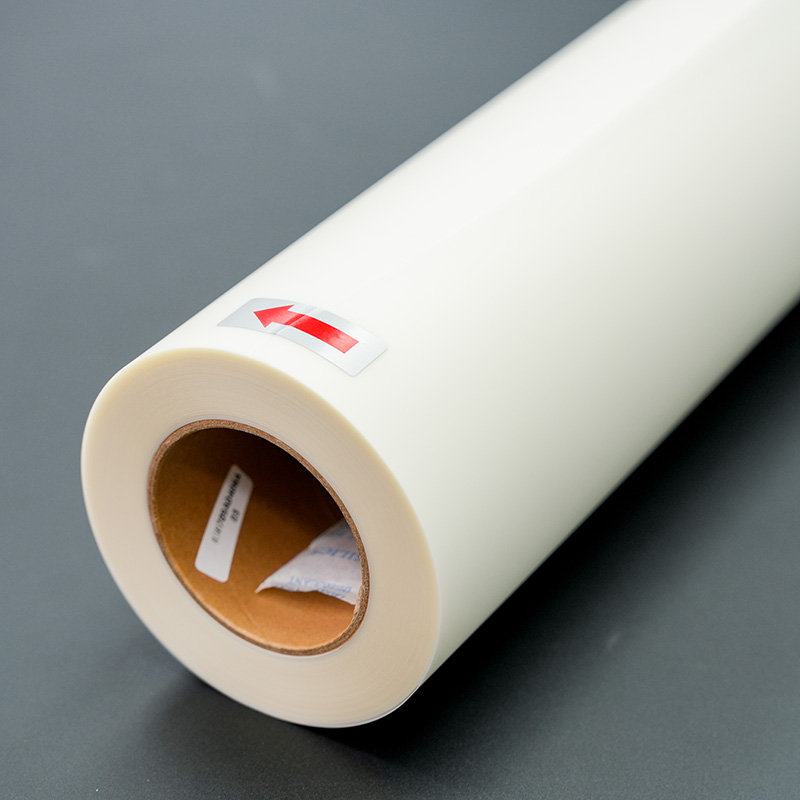

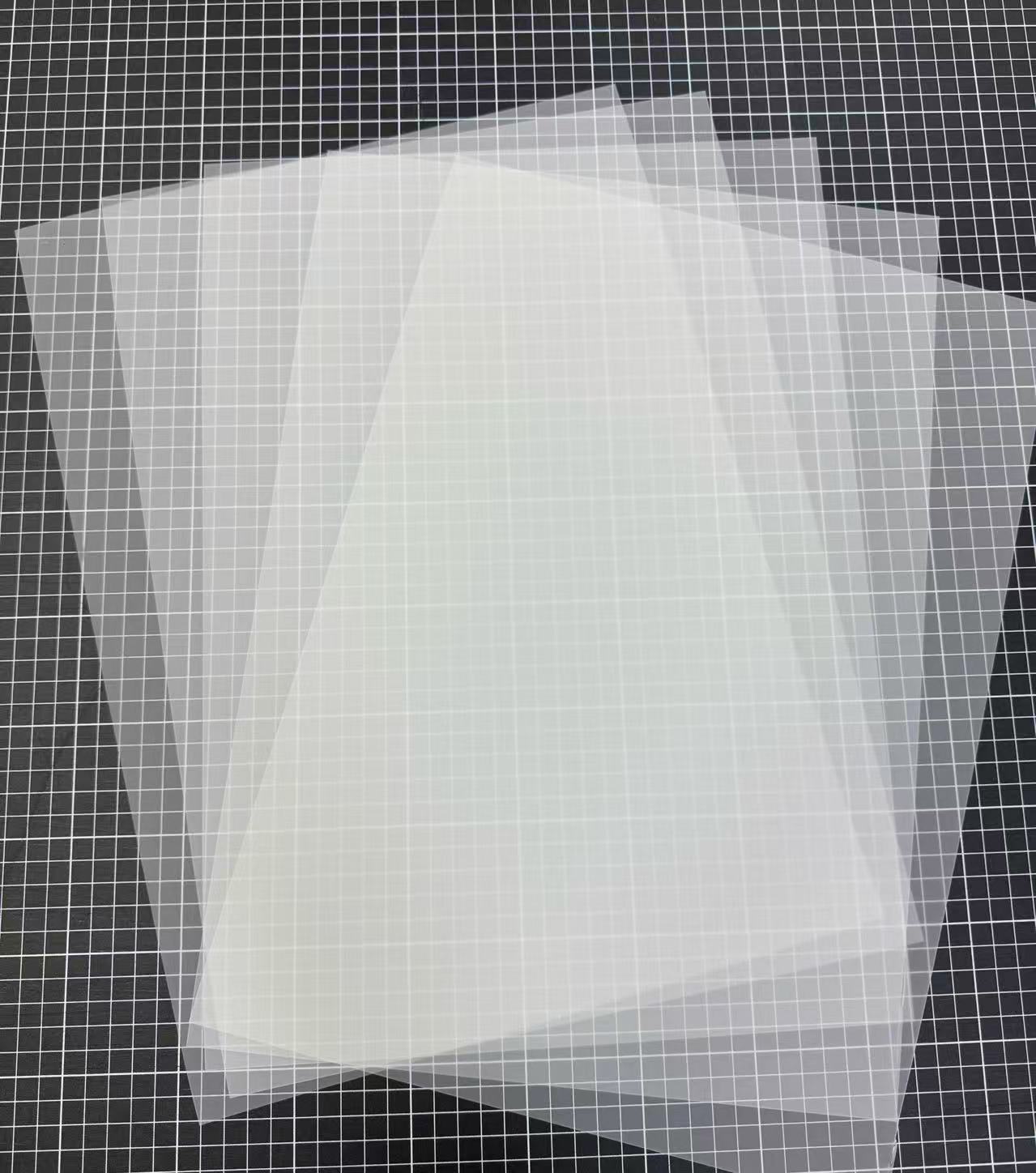

PET Film: The process begins with a special piece of PET (Polyethylene Terephthalate) film. This film is coated with a special substance that plays a crucial role in the transfer of designs. The coating on the PET film acts as a receptive layer for the inks and the adhesive powder, ensuring that the design adheres properly during the transfer process. It has a smooth surface that enables the inks to be precisely deposited, resulting in sharp and detailed prints.

Water - based Inks: Water - based inks are used in DTF printing due to their numerous advantages. They are environmentally friendly, as they contain fewer volatile organic compounds (VOCs) compared to solvent - based inks. These inks are also known for their excellent color vibrancy and fast - drying properties. They can produce a wide gamut of colors, allowing for the reproduction of even the most complex and vivid designs. The water - based nature of the inks also means that they are safe to use on fabrics that come in contact with the skin, making DTF - printed garments suitable for everyday wear.

Special Adhesive Powder: After the design is printed onto the DTF film using water - based inks, a special adhesive powder is applied. This powder, often made of a thermoplastic material, is the key to transferring the design from the film to the fabric. When heat is applied during the transfer process, the adhesive powder melts and forms a strong bond between the printed design and the fabric, ensuring the durability of the final print.

The Printing Process

Design Creation and Printing: First, the desired design is created using graphic design software on a computer. This can range from simple logos to intricate, multi - colored patterns. Once the design is finalized, it is sent to a DTF printer. The DTF printer uses a piezoelectric printhead to precisely deposit the water - based inks onto the DTF film. The printhead moves back and forth across the film, layer by layer, building up the design.

Adhesive Powder Application: Immediately after the printing is complete, while the inks are still wet, the special adhesive powder is evenly spread over the printed design on the DTF film. This can be done manually using a powder - spreading tool or automatically with the help of a powder - shaking machine. The goal is to ensure that every part of the printed design is covered with the adhesive powder, as this will determine how well the design adheres to the fabric during the transfer.

Heat - Transfer to Fabric: The next step involves using a heat press machine. The printed DTF film with the adhesive - covered design is placed on top of the fabric, and the heat press is activated. The heat press applies both heat and pressure to the assembly. The heat causes the adhesive powder to melt, and the pressure helps to bond the melted adhesive and the printed design firmly onto the fabric. The temperature and pressure settings of the heat press are carefully calibrated depending on the type of fabric and the thickness of the materials being used. For example, thinner fabrics may require lower heat and pressure settings to avoid damage, while thicker materials may need more intense heat and pressure to ensure a proper transfer.

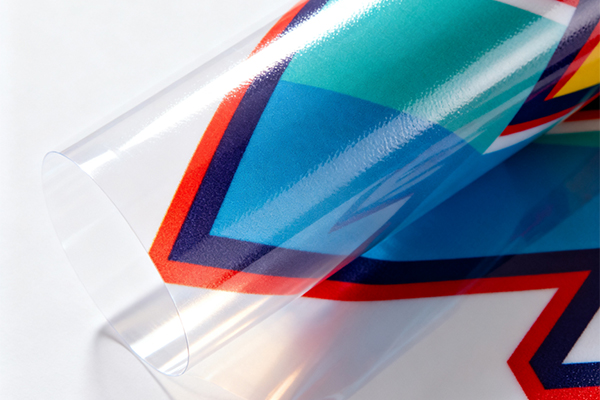

Film Removal: After the heat - transfer process is complete and the fabric has cooled down slightly, the DTF film is carefully peeled off. This leaves behind the printed design on the fabric, with the adhesive powder having formed a durable bond between the inks and the fabric fibers.

Advantages of DTF Printing

Durability: The prints produced by DTF printing are highly durable. The combination of water - based inks and the adhesive powder creates a strong bond with the fabric, making the design resistant to fading, cracking, and peeling, even after multiple washes. This makes DTF - printed products suitable for long - term use and ensures customer satisfaction.

High - Quality and Detailed Designs: DTF printing can achieve a high level of detail in the designs. The precision of the DTF printer, along with the ability of water - based inks to produce sharp edges and smooth gradients, allows for the reproduction of intricate patterns, fine lines, and high - resolution images. Whether it's a detailed photograph or a complex graphic design, DTF printing can bring it to life on fabric with remarkable clarity.

Versatility in Fabric Types: Another significant advantage of DTF printing is its compatibility with a wide range of fabrics. It can be used on natural fibers such as cotton, linen, and silk, as well as synthetic fibers like polyester, nylon, and blends of these materials. This versatility makes DTF printing suitable for a variety of applications, from fashion apparel to home textiles.

Cost - Effectiveness for Small Batches: For small - scale production runs or custom orders, DTF printing can be a cost - effective option. Since there is no need for expensive setup processes like screen - making, as in traditional screen printing, the cost per unit for small batches is relatively low. This makes it an attractive choice for small businesses, start - ups, and individuals who want to produce custom - printed items without a large upfront investment.

contact us

contact

Tel: +86 17706217416

Add: Building L2A, No. 520, Lane 1588, Zhuguang Road, Hongqiao World Center, Qingpu District, Shanghai, China