The Recommendation of Different Types of BOPP Film Surface Finish

Introduction to BOPP Surface Finishes

BOPP films are available in a broad range of surface finishes to meet the aesthetic and functional needs of the flexible packaging industry. The most commonly recommended finishes include white and opaque, matte, glossy, and metallized surfaces, each offering unique visual effects and performance characteristics. Additionally, corona treatment is often applied to improve printability and adhesion. Understanding how these finishes differ helps converters select the most suitable BOPP film for specific packaging applications.

White and Opaque BOPP Film

White and opaque BOPP films are widely recommended for packaging that requires strong visual impact and brand enhancement. Their high opacity provides excellent light-blocking properties, making them ideal for snacks, confectionery, and dairy products that are sensitive to light exposure. White and opaque films also offer superior coverage, enabling bold graphics and vibrant colors during printing. When combined with corona treatment, these films deliver optimal ink adhesion and consistent printing performance. For converters seeking strong shelf appeal, white and opaque BOPP films remain a top choice.

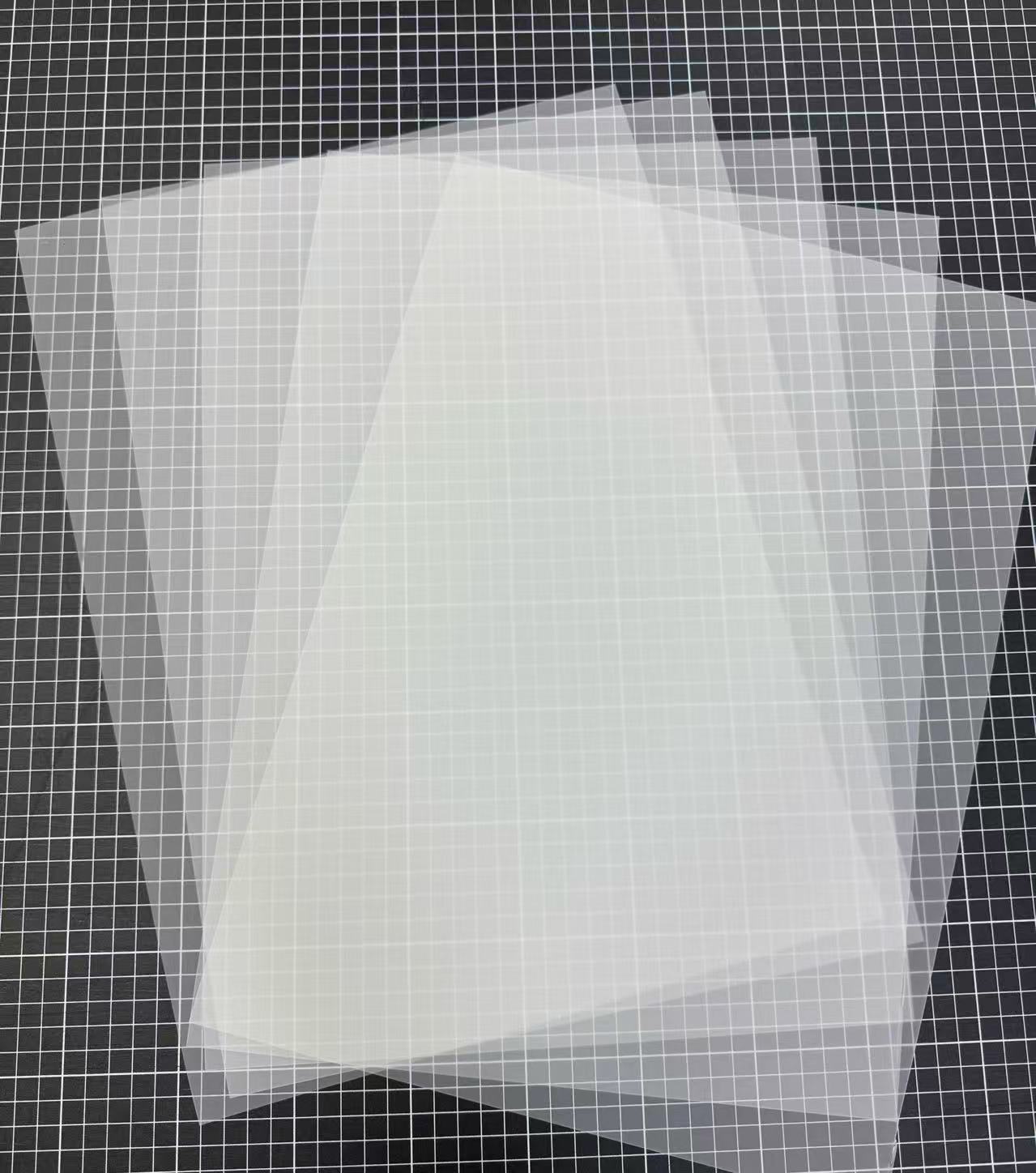

Matte BOPP Film

Matte BOPP films are recommended for brands seeking a premium, soft-touch appearance. The matte surface finish reduces glare and enhances readability, making it suitable for high-end food packaging, personal care products, and luxury items. The elegant, low-shine look of matte films pairs well with both solid colors and detailed graphics. Many matte BOPP films undergo corona treatment to ensure high-quality printing results, even with fine designs. This combination of aesthetics and functionality makes matte finishes a preferred option in sophisticated packaging markets.

Glossy BOPP Film

For applications requiring brightness and clarity, glossy BOPP filmsare highly recommended. Their reflective surface enhances color saturation and visual sharpness, making them ideal for consumer goods packaging. Glossy BOPP films are widely used for bakery, snacks, frozen foods, and personal care products where high visual impact is essential. To maximize print performance, many glossy films feature corona treatment, which improves ink bonding and reduces defects. As a result, glossy BOPP film continues to be a popular choice for vibrant, eye-catching packaging.

Metallized BOPP Film

When superior barrier properties are required, metallized BOPP films offer the optimal solution. The metallized finish provides outstanding protection against oxygen, moisture, and light, making it suitable for coffee, dry foods, snacks, and seasonings. The shiny, metallic appearance also creates a premium visual effect, enhancing brand presentation. Like other finishes, corona treatment is commonly recommended for metallized BOPP films to ensure reliable printing and lamination performance. Their blend of aesthetics and barrier strength makes metallized films a standout category.

Conclusion

Whether a brand requires the boldness of white and opaque, the elegance of matte, the brilliance of glossy, or the functionality of metallized BOPP films, each surface finish offers unique advantages. Combined with essential corona treatment, these BOPP film options provide converters with reliable performance, strong visual appeal, and exceptional versatility for modern flexible packaging needs.

contact us

contact

Tel: +86 17706217416

Add: Building L2A, No. 520, Lane 1588, Zhuguang Road, Hongqiao World Center, Qingpu District, Shanghai, China