How to Convert Substrate BOPP Film Into Label Facestock

Introduction

In today's labeling industry, substrate BOPP film has become a preferred material for manufacturing durable and high-quality labels. The process of converting substrate BOPP film into BOPP film for label facestock involves several controlled steps that ensure excellent performance, adhesion, printability, and converting efficiency. As demand continues to rise for premium labels across beverages, personal care, household chemicals, and food packaging, the importance of producing reliable BOPP labeling film becomes increasingly significant.

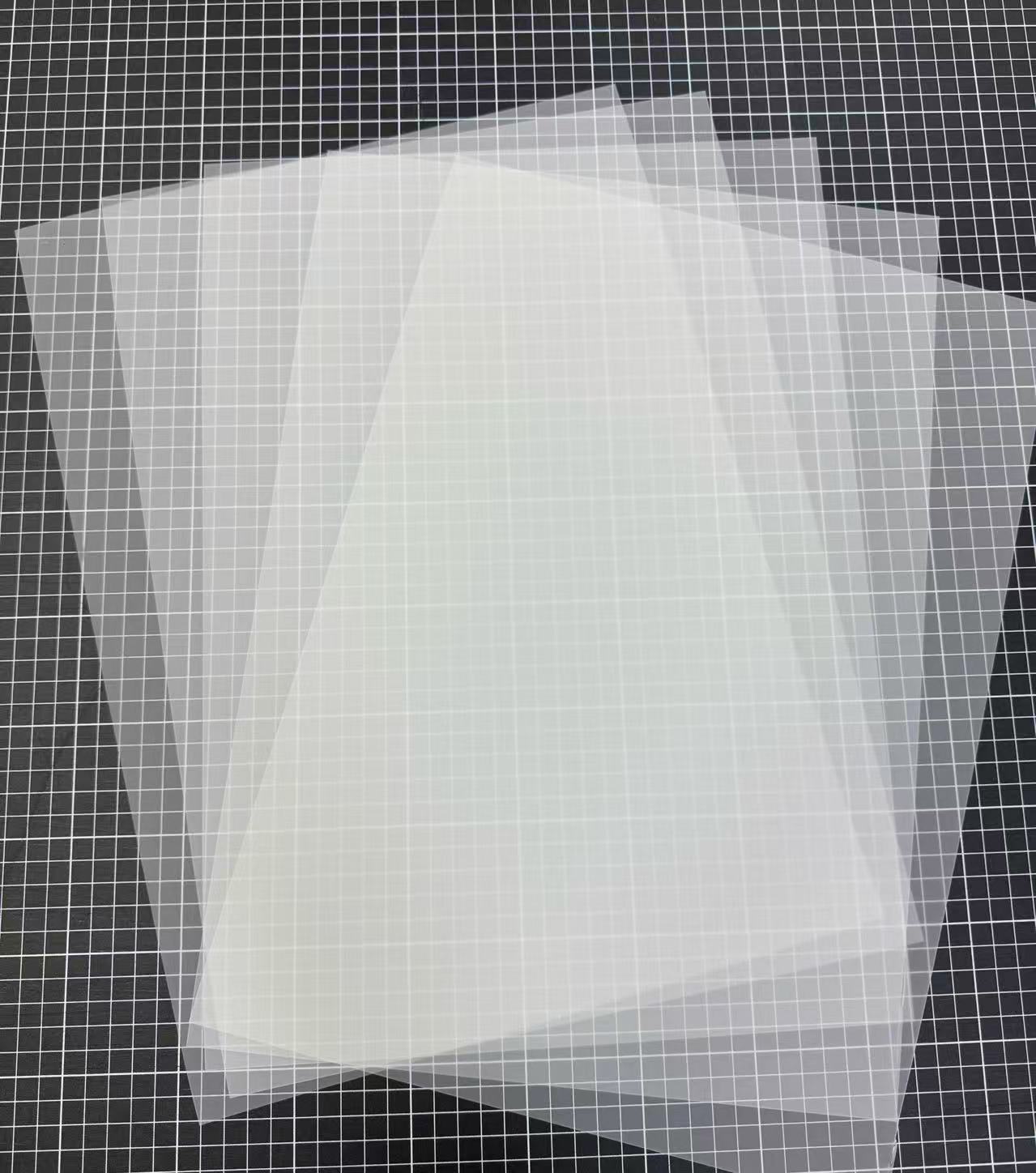

Selecting the Right Substrate BOPP Film

The first step in producing BOPP film for label facestock is choosing the appropriate substrate BOPP film. The selected base film must offer outstanding clarity, stiffness, low shrinkage, and consistent thickness. These properties ensure smooth processing during coating and printing. Not all substrate films behave the same, so converters must evaluate tensile strength, slip levels, surface energy, and dimensional stability. A high-quality substrate BOPP film provides a dependable foundation for creating a top-performing BOPP labeling film.

Surface Treatment for Improved Adhesion

To transform raw substrate BOPP film into functional BOPP film for label facestock, surface treatment is essential. The most common method is corona treatment, which increases surface energy and helps inks, adhesives, and coatings adhere properly. Without proper treatment, BOPP labeling film may suffer from ink lift, coating defects, or adhesive failure. By applying consistent and controlled surface treatment, converters ensure that the substrate BOPP film becomes fully suitable for high-quality printing and lamination.

Coating the Substrate BOPP Film

The next critical step is the application of functional coatings. To create BOPP film for label facestock, converters often apply topcoats or print-receptive coatings designed for UV, flexographic, or digital printing systems. Coatings enhance ink anchorage, gloss, and scratch resistance. On the opposite side, adhesives or primer layers can be applied depending on the label construction. This coating stage is where the substrate BOPP film truly transforms into a specialized BOPP labeling film capable of meeting the performance demands of label converters and brand owners.

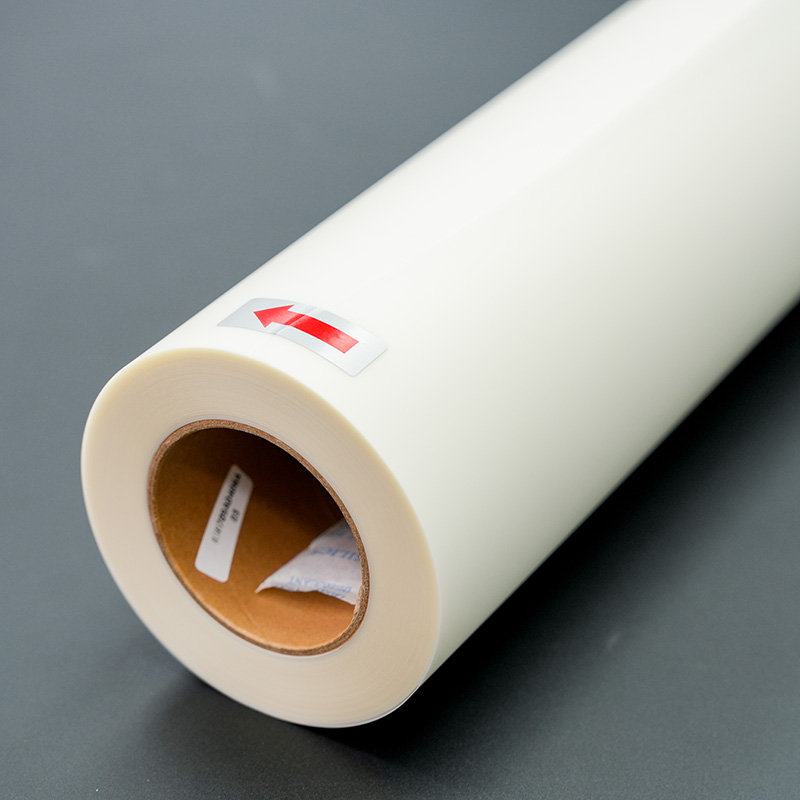

Slitting and Converting into Label Rolls

Once coated and treated, the finished BOPP film for label facestock is slit into custom widths and wound into rolls suitable for label converting machines. Precise slitting ensures smooth processing during die-cutting and dispensing. During this stage, quality control checks verify that the BOPP labeling film maintains uniform tension, good flatness, and flawless surface quality. Properly converted rolls ensure efficient downstream production of pressure-sensitive labels, wrap-around labels, and specialty labeling applications.

Conclusion

Converting substrate BOPP film into BOPP film for label facestock is a multi-step process involving film selection, surface treatment, coating, and precise slitting. Each step plays a vital role in ensuring the final BOPP labeling film delivers excellent printability, durability, and converting performance. With careful control and optimized production, converters can create high-quality label materials that meet the growing demands of global packaging markets.

News & Events

learn more-

Blog

Press Release Dec-11-2025

Blog

Press Release Dec-11-2025What's the Advantage of BOPP Films Over Traditional Packaging Film

BOPP Film has become one of the most widely used materials in the global packaging industry, especially for food products, consumer goods, and daily-use items. Compared with traditional packaging materials such as PVC, PE, or PET films, BOPP Film offers a variety of functional, economic, and environmental advantages. -

Blog

Press Release Dec-11-2025

Blog

Press Release Dec-11-2025The Recommendation of Different Types of BOPP Film Surface Finish

BOPP films are available in a broad range of surface finishes to meet the aesthetic and functional needs of the flexible packaging industry. -

Blog

Press Release Dec-11-2025

Blog

Press Release Dec-11-2025The Types of BOPP Films for Flexible Package Industry

BOPP films, or biaxially oriented polypropylene films, are essential materials widely used in the flexible packaging industry. Known for their clarity, strength, barrier properties, and suitability for printing and lamination, BOPP films support a broad range of applications across food, consumer goods, and industrial packaging. As packaging performance requirements continue to rise, different types of BOPP films have been developed to meet specific functional and aesthetic needs throughout the supply chain.

contact us

contact

Tel: +86 17706217416

Add: Building L2A, No. 520, Lane 1588, Zhuguang Road, Hongqiao World Center, Qingpu District, Shanghai, China