The Pros and Cons of DTF film printing: A Comprehensive Guide

In the dynamic world of custom apparel printing, b...

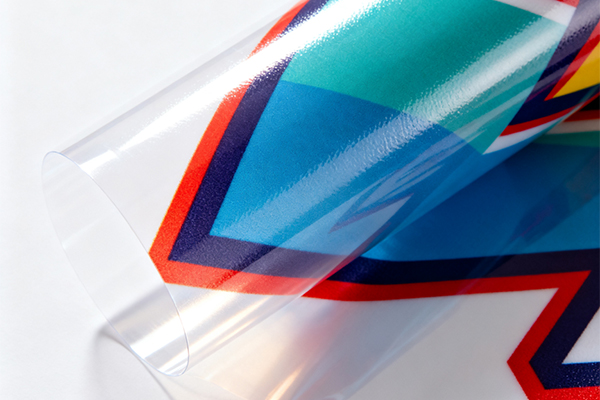

MoreDirect to Film (DTF) printing paper, often referred to as DTF transfer paper or DTF PET film, is a specialized carrier substrate engineered for use in DTF printing processes. Its primary function is to temporarily hold specially formulated DTF inks, both white and color, which are then cured, powdered with a hot-melt adhesive polymer, and finally heat-pressed onto a wide array of textiles and other materials. This innovative substrate is the cornerstone of the DTF transfer method, enabling the creation of a flexible, durable, and high-fidelity transfer that can be applied to cotton, polyester, blends, leather, denim, and even some hard surfaces. The paper itself is typically a polyethylene terephthalate (PET) film, chosen for its stability, release properties, and ability to produce a consistent, high-quality transfer film that separates cleanly from the printed design during the heat press application, leaving the ink and adhesive layer perfectly adhered to the final product.

The application of DTF printing paper has revolutionized the garment decoration and custom printing industries by offering unparalleled versatility and print quality. Market analysis and industry reports from sources like Smithers and Grand View Research consistently highlight the rapid growth of the digital textile printing market, within which DTF is a significant and expanding segment. A key driver is the technology's ability to print on 100% cotton, a task where Direct to Garment (DTG) has traditionally excelled, but also on high-polyester content fabrics and blends, which are challenging for many other methods. Search trend data from platforms like Google Trends and keyword analysis tools show a marked and steady increase in search volumes for terms such as "DTF printing," "DTF transfers," and "DTF paper" over the past three years, indicating surging interest from both businesses and consumers. This is corroborated by user-generated content on platforms like YouTube, where tutorials on DTF printing using DTF paper garner hundreds of thousands of views, demonstrating a widespread and practical adoption. The primary application is in the production of custom apparel, including t-shirts, hoodies, sportswear, and caps. However, its use has expanded to accessories like bags and shoes, as well as niche markets such as personalized pet bandanas and home decor items. The ability to produce small batches and one-off designs cost-effectively, without the need for screens or minimum orders, makes DTF paper an essential tool for print-on-demand businesses, e-commerce stores, and small to medium-sized enterprises seeking to offer a wide range of customized products.

The advantages of using DTF printing paper are extensive and well-documented through user testimonials, case studies, and comparative analyses published in trade magazines such as "Printwear" and "Impressions." The most frequently cited benefit is the exceptional durability and softness of the final print. Unlike some traditional methods that leave a stiff, plastic-like feel, a properly executed DTF transfer using quality paper results in a flexible, breathable, and crack-resistant finish that withstands repeated washing and commercial laundering. This performance is directly linked to the quality of the DTF paper, which ensures a complete and clean release of the ink and adhesive layer. Furthermore, DTF printing with dedicated paper offers a superior color vibrancy and opacity, especially on dark garments, due to the opaque white ink layer that is printed underneath the colors. This eliminates the need for pre-treatment of garments, a necessary and time-consuming step in DTG printing. Operational advantages are also significant. Data from equipment manufacturers and consumable suppliers often highlight the reduced operational complexity and lower barrier to entry compared to DTG. DTF printers using this paper are less prone to clogging from the white ink, a common issue in DTG, leading to higher uptime and productivity. The transfers themselves can be pre-printed, stored, and applied on-demand, decoupling the printing process from the final application and allowing for greater production flexibility and faster order fulfillment times for businesses.

When selecting and applying DTF printing paper, practical considerations backed by technical specifications and user feedback are paramount for achieving optimal results. The choice of paper is not one-size-fits-all; it must be compatible with the specific DTF printer, inks, and adhesive powder being used. Technical data sheets from leading manufacturers like Hi-Fi Transfers, DTF Transfers Plus, and ASUB highlight critical parameters such as film thickness (typically ranging from 50 to 75 microns), surface tension for optimal ink adhesion, and the glass transition temperature (Tg) of the coating to ensure proper release. A common metric for performance, often discussed in online forums and user groups, is the release rate. High-quality DTF paper should allow for a near 100% transfer of the ink and adhesive layer to the substrate, leaving minimal to no residue on the PET film after peeling. The application process itself involves precise parameters. Industry-standard guidelines, frequently published by heat press manufacturers such as Stahls' and Pro World, specify that successful application requires a specific combination of heat, pressure, and time. Typical settings involve a heat press temperature between 150°C to 165°C (302°F to 329°F) applied with medium to high pressure for approximately 12 to 15 seconds. Adherence to these data-driven parameters is crucial; deviation can lead to issues like poor adhesion, cracking, or a ghosting effect where the film's texture is visible on the transfer. Finally, post-application, a cold peel after the transfer has cooled down is widely recommended by experts to ensure the adhesive has fully set, resulting in the highest possible wash fastness and durability of the final product.

Select the most popular foreign trade service products to meet your diverse needs

Learn more about the dynamics and professional knowledge of the foreign trade industry

In the dynamic world of custom apparel printing, b...

More

Flexo printing uses flexible plates to create high...

More

When it comes to transferring designs onto objects...

More

When diving into Direct-to-Film (DTF) printing, on...

More

If you’re new to garment printing, using DTF film ...

MoreSelect the most popular foreign trade service products to meet your diverse needs

Explore more content related to foreign trade services

Tel: +86 17706217416

Add: Building L2A, No. 520, Lane 1588, Zhuguang Road, Hongqiao World Center, Qingpu District, Shanghai, China

User Comments

Service Experience Sharing from Real Customers

Jennifer Martinez

Graphic DesignerThe DTF transfer paper produces incredibly vibrant colors and fine details. Our t-shirt designs have never looked better!

David Chen

Print Shop OwnerExcellent adhesion and durability on various fabrics. Our customers love the soft hand feel and professional results.

Sarah Johnson

Production ManagerConsistent performance with minimal powder waste. Makes our DTF printing process much more efficient and cost-effective.

Michael Brown

Small Business OwnerPerfect for custom merchandise with complex designs. The transfer quality exceeds our expectations every time.