DTF FILM Holiday Sales Strategy 101: Can You Turn 1 Customer Into 5?

The holiday season brings a flood of new customers...

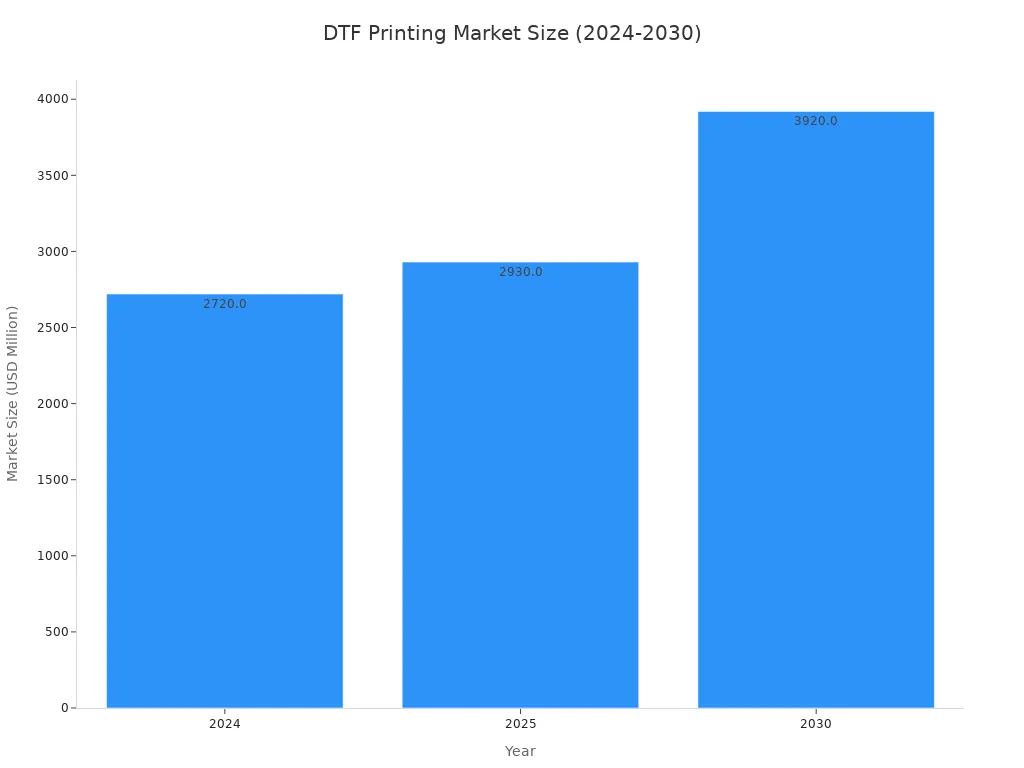

MoreThe most critical factor in selecting a dtf pet transfer film is its compatibility with a specific printer and ink set. This alignment prevents poor ink adhesion, color deviations, and peeling issues. The Direct-to-Film printing industry shows significant expansion, underscoring the need for precise material selection.

| Metric | Value |

|---|---|

| Market size in 2024 | USD 2,720.0 million |

| Projected market size by 2030 | USD 3,920.0 million |

| CAGR (2025-2030) | 6.0% |

The physical characteristics of a printer directly influence the type of film required for optimal performance. A film designed for a high-speed commercial machine will likely cause issues in a smaller desktop unit, and vice versa. Operators must align their film choice with their specific hardware.

Desktop printers are often standard inkjet models converted for DTF printing. These smaller machines, such as modified Epson L1800 or P600 printers, operate at slower speeds. They also have less sophisticated media transport systems. Films for these printers possess specific qualities.

Flexibility: They are generally more pliable to navigate the tight paper paths of desktop units.

Lower Temperature Tolerance: The film's coating is formulated to accept ink effectively with the lower heat output common in these setups.

Format: Suppliers typically offer these films in sheets (e.g., A4, A3) or small-width rolls.

Choosing a film made for a larger machine can lead to feeding errors and inconsistent ink application.

Wide-format printers are built for high-volume, roll-to-roll production. These systems run at significantly higher speeds and generate more heat. The dtf pet transfer film used must withstand these demanding conditions. A key requirement is rigidity. The film needs to be stiff enough to handle the tension of the take-up system without buckling or warping.

Note: A film that is too flexible can easily crease or shift during printing on a wide-format machine. This misalignment ruins prints and causes significant material waste. Commercial-grade films ensure stability from the print head to the powdering station.

These films are almost exclusively sold in large rolls, typically 24 inches (60cm) or wider, to match the printer's dimensions.

Ink and film work as a system. The chemical properties of the ink must align with the film's receptive coating for a successful transfer. Using an incompatible pair leads to poor ink adhesion, color bleeding, and prints that fail after washing. Operators must confirm that their chosen film is engineered for their specific ink set.

Most DTF printing uses specialized water-based pigment inks. These inks contain several key components that interact directly with the film's coating. The formulation includes pigments, resins, and adhesive elements that allow the ink to sit on the film before transfer. A high-quality dtf pet transfer film has a coating designed to manage these properties:

Binders: Polyurethane and acrylic resins in the ink act as a glue. They provide the elasticity needed for a durable, stretch-resistant print.

Solvents: The water-based carrier controls drying time and ink flow. The film's coating must absorb this moisture at an optimal rate.

Surface Tension: Surfactants in the ink control how it spreads on the film. A compatible coating prevents the ink from beading up or spreading too far, ensuring sharp details.

UV DTF printing is a different technology that uses ultraviolet light to cure the ink instantly. This process requires a completely different type of film system, often called an "A/B" film set. Standard DTF films will not work with UV inks. The UV-curable ink and varnish require a special release liner and adhesive film to create the final "sticker."

Important: Always source films specifically designated for UV DTF applications. Reputable suppliers like Yesion, DTG PRO, and Digitech offer products engineered exclusively for this process, ensuring reliable adhesion and transfer. Using the wrong film will result in complete failure.

The peel type—cold, warm, or hot—defines when an operator can remove the film from the garment after heat pressing. This choice directly impacts production speed, final texture, and the level of detail a print can hold. Aligning the peel type with the job requirements is essential for an efficient and successful workflow.

Cold peel films require the transfer to cool down completely before the operator peels the film away. This cooling period allows the adhesive to fully bond with the fabric, resulting in superior durability and wash resistance. This method excels at preserving fine lines and intricate patterns, making it the top choice for retail-quality apparel.

Operators should follow a precise process for the best results:

Set the heat press to the correct temperature for the fabric, such as 315°F (157°C) for cotton.

Apply medium pressure for 10–15 seconds.

Allow the garment and transfer to cool completely to room temperature.

Peel the film smoothly and evenly.

Perform a final press for 3–5 seconds with parchment paper to seal the design.

Hot and warm peel films are engineered for speed. Operators can peel the film immediately (hot peel) or after just a few seconds (warm peel) post-press. This significantly accelerates production, making this dtf pet transfer film ideal for high-volume orders and fast-turnaround jobs. For cotton blends, a heat press temperature of 300–320°F (150–160°C) is typical.

While faster, this method may offer slightly less durability and can sometimes struggle with extremely fine details compared to cold peel. The choice between them depends on the priority: speed versus intricate detail and maximum longevity.

Comparison at a Glance:

Feature Hot Peel Cold Peel Production Speed ⚡ Faster, for high-volume orders 🐢 Slower, requires cooling time Detail Retention Good for standard designs Excellent for fine lines & text Durability Good durability Superior durability & washability Best Use Case Speed and volume production Retail quality and intricate designs

The finish of a dtf pet transfer film—specifically, whether it is single-sided or double-sided—plays a crucial role in both print quality and machine performance. The coating on the print side affects ink absorption, while the finish on the reverse side impacts how the film feeds through the printer.

A single-sided film has a coating on just one side: the print side. This matte surface is engineered with a reinforced, uniform layer that ensures stable and consistent ink absorption. The PET material itself has a high ink absorption rate, which helps produce sharper and more vivid designs. This type of film is a standard choice for many applications, especially in sheet-fed or desktop printer setups where media transport is less demanding. The primary focus of a single-sided film is to create an optimal surface for the ink to adhere to before the powdering and curing stages.

Double-sided films feature a specialized coating on both sides. While one side is the printable surface, the reverse side has an anti-slip and anti-static coating. This design is critical for roll-to-roll and high-speed commercial printers.

The non-printable matte or glossy side increases friction as the film moves through the printer. This feature significantly improves feeding accuracy, prevents slippage, and helps reduce jams.

The benefits of a double-sided coating are clear for high-volume production:

Anti-Slip Property: The reverse coating grips the printer's rollers, preventing the film from shifting during printing.

Improved Registration: Stable feeding ensures the print layers align perfectly, which is essential for maintaining sharp details.

Anti-Static Function: This coating reduces static buildup, which can otherwise attract dust and cause print defects.

Film thickness, measured in microns, directly influences handling, durability, and printer compatibility. A film’s rigidity determines how well it resists curling under heat and moves through a printer’s transport system. Operators must select a thickness that aligns with their equipment and production demands to prevent feeding errors and material waste.

The industry standard for DTF film is 75 microns. This thickness provides a balanced combination of flexibility and rigidity, making it easier to handle and reducing the chance of wrinkles during heat pressing. Its versatility makes it a reliable choice for most applications.

Versatility: It works effectively on materials like cotton, polyester, and blends.

Broad Suitability: It is ideal for both small print shops and large commercial productions.

High-Quality Results: It produces vibrant prints with a soft feel and excellent washability.

However, some desktop printers, like the ET-8550, can have trouble with the feeding mechanism for any film. The printer's sensors may fail to properly engage the material. Operators often apply a strip of painter's tape to the film's leading edge to improve sensor detection and ensure a successful feed.

Thicker films, typically 100 microns or more, offer enhanced stability and are designed for more demanding situations. Their primary advantage is superior performance during the heat-curing stage. Thinner, single-sided films are more prone to curling at the edges when heat is applied.

Thicker films possess greater structural integrity. This enhanced stability directly reduces the film's tendency to curl during the curing process, ensuring the powdered adhesive remains undisturbed.

This rigidity is especially beneficial in high-speed, roll-to-roll systems where film flatness is critical for preventing head strikes and maintaining consistent quality. The added stiffness also simplifies handling and positioning on the garment before pressing.

The receptive coating is the most critical component of a DTF film. Its quality determines ink absorption, color vibrancy, and final transfer durability. A consistent, well-formulated coating is the foundation of a professional-grade print. Operators must learn to distinguish between high- and low-quality films to avoid production failures.

A superior coating feels smooth and uniform to the touch, with no visible defects or inconsistencies. It provides a stable surface that prevents ink from bleeding, ensuring sharp lines and details. One key indicator of quality is industry certification. The OEKO-TEX Standard 100 certification, for example, confirms a product is free from harmful substances. Some leading films, like Dae Ha's Hot Peel Film, have achieved this standard. This certification also extends to consumables like US-made Quatro inks, signaling a commitment to safety and quality across the entire DTF system.

A poor-quality coating is a direct cause of print defects and material waste. It often feels uneven or may have visible blemishes. These inconsistencies lead to significant problems during and after printing.

An inconsistent coating cannot properly manage ink, leading to poor adhesion and prints that fail prematurely.

Operators should watch for these common signs of a bad film:

Poor Adhesion: The design peels, flakes, or fades after pressing or washing, indicating the ink and adhesive did not bond correctly to the fabric.

Incomplete Transfer: Parts of the design fail to release from the film, leaving the final print with missing pieces and a lack of clarity.

Film Wrinkling: The film creases during printing or pressing, which distorts the final image and causes alignment problems.

Visible Defects: Dust particles or contaminants on the film create small holes or stains in the print, which are especially noticeable in white ink layers.

Even with extensive research, a film’s real-world performance is only revealed through testing. Integrating a new film into a production workflow without sampling is a significant financial risk. A small test run can prevent large-scale failures, saving valuable time, ink, and materials.

Sampling is a critical quality control measure. It allows operators to verify a film's compatibility with their specific printer, ink, and powder before committing to a bulk purchase. This step confirms that the film meets performance expectations and helps establish a reliable production process.

A single failed production run due to an untested film can cost more than an entire roll of high-quality material. Testing is an investment, not an expense.

By validating a film sample, print shops can confidently produce consistent, high-quality transfers that meet client standards and protect their profit margins.

A systematic evaluation provides a complete picture of a film's performance. Operators should follow a standard checklist to assess every critical attribute from initial inspection to the final wash test.

Physical Inspection: Examine the film for a smooth, uniform coating free of scratches or defects. The coating should not scrape off easily with a fingernail.

Print Quality: Print a test design with fine lines and solid color blocks. Check for even ink absorption, sharp details, and accurate color without any ink bleed or "water edges."

Powder and Curing: After applying powder, ensure it shakes off cleanly from non-printed areas. The film must remain stable and not wrinkle or yellow during the heat-curing process.

Transfer and Washability: Press the design onto a test garment. Assess the peel quality—it should be clean and complete. Finally, perform several wash cycles to confirm the transfer's durability and resistance to fading or peeling.

Systematically checking the seven points is an operator's roadmap to success. Successful printers, like DTF North Carolina, source premier films to achieve vibrant colors and sharp edges. This practice eliminates waste, saves time, and ensures the production of high-quality, durable prints that satisfy clients and grow a business.

No. Manufacturers design DTF films for single-use applications only. The receptive coating is consumed during the initial transfer process, making reuse impossible and guaranteeing print failure on subsequent attempts.

Film curling often results from excessive heat or using a film that is too thin. Thinner, single-sided films are more susceptible. Operators should consider using thicker films (100+ microns).

Poor ink adhesion typically stems from an incompatible ink and film pairing. A low-quality or inconsistent film coating also prevents the ink from bonding correctly to the surface.

Select the most popular foreign trade service products to meet your diverse needs

Learn more about the dynamics and professional knowledge of the foreign trade industry

The holiday season brings a flood of new customers...

MoreIf you’re new to garment printing, using DTF film ...

MoreChristmas Special Heat Transfer Film is your ulti...

MoreSelect the most popular foreign trade service products to meet your diverse needs

Explore more content related to foreign trade services

Tel: +86 17706217416

Add: Building L2A, No. 520, Lane 1588, Zhuguang Road, Hongqiao World Center, Qingpu District, Shanghai, China

User Comments

Service Experience Sharing from Real Customers

Michael Rodriguez

Production ManagerThis DTF PET film roll is exceptional. The consistent thickness and perfect release properties have drastically reduced our transfer failures. It's become a staple in our production line for high-quality garment printing.

Sarah Chen

Graphic DesignerAs a designer, the clarity and color vibrancy I achieve with this film are outstanding. It handles intricate details perfectly, and the rolls are always flawlessly wound with no static issues. Highly recommended for precision work.

David Kim

Shop OwnerGreat product for our small business. The film is durable, cuts cleanly, and the adhesive performs well on various fabrics. The roll length offers good value. We've seen a noticeable improvement in our final product quality.

Jessica Williams

Operations LeadThis PET film has optimized our workflow. Its excellent dimensional stability prevents misalignment during transfers, and the consistent quality from roll to roll means no surprises. A reliable and high-performance material for professional DTF printing.