DTF FILM Application

DTF Film Application in Textile Industry

-

Advantages of Using DTF film in textile industy

Hot-peel DTF film offers a versatile, cost-effective solution for textile printing, delivering vibrant colors, strong durability, and compatibility with a wide range of fabrics. Its efficient process and eco-friendly options make it ideal for both mass production and custom apparel. -

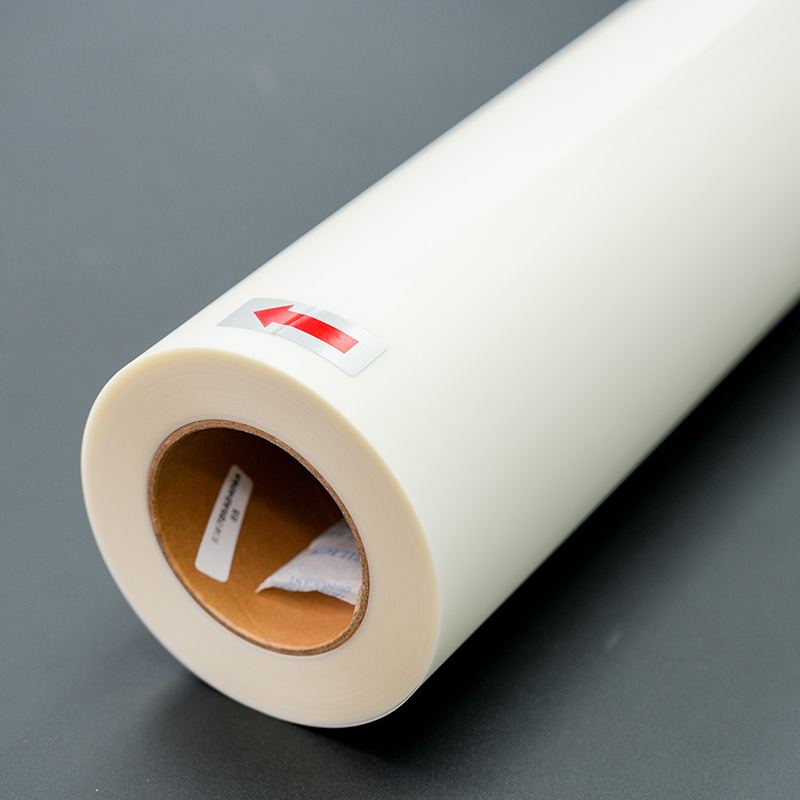

Why Use SALLAGE DTF film?

Saillage DTF FILm is the only water-based coating in China, which is eco-friendly. Thanks to the multi-functional coating technology, saillage DTF film dry super fast, deliver a high color reproduction, easy to peel whether hot,cold or instant. Use saillage DTF film not only increase your product quality, but also increase your production efficiency, make all the customers satisfied

Become Our Agent

DTF film vs Sublimation paper

| FEATURES | DTF | SUBLIMATION |

|---|---|---|

| Substrates | Works on all fabrics (cotton, polyester, blends) | Only works on polyester or polymer-coated materials. |

| Design Opacity | Opaque; visible on dark fabrics. | Translucent; best on light/white polyester. |

| Durability | Medium durability. Designs may crack or peel over time. | Highly durable. Ink bonds with fabric fibers, resisting heavy use. |

| Cost | Affordable setup and materials – budget-friendly. | Higher equipment and material costs – ideal for high-volume use. |

FAQs of Using DTF Films in Textile

-

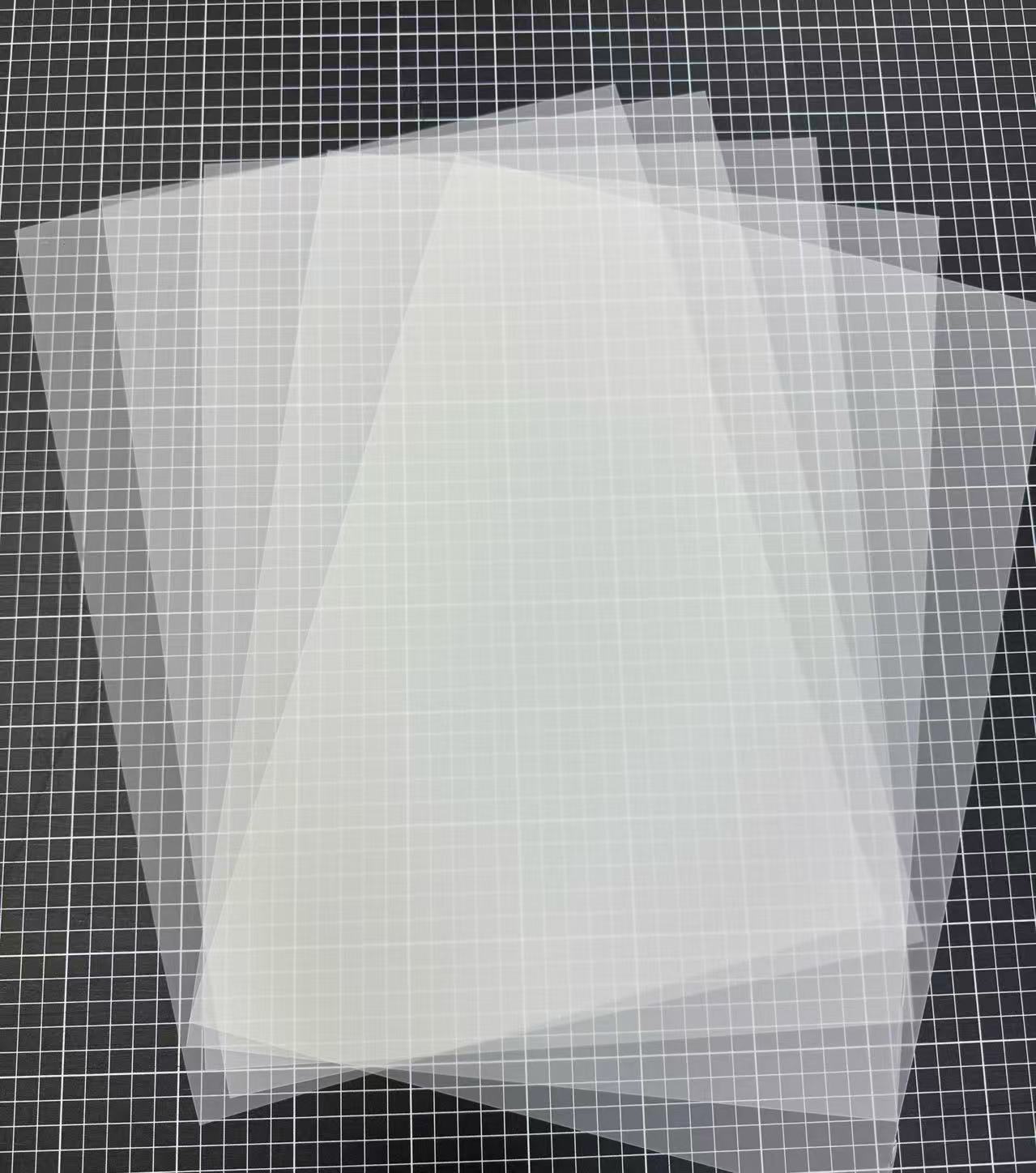

What is DTF Film, and How Does It Work?

DTF (Direct to Film) film is a PET-based film coated with a printable surface. The process

involves:

Printing CMYK + white ink onto the film.

Applying hot-melt adhesive powder.

Curing the film with heat.

Heat-pressing the design onto fabric or other substrates.

Key advantage: Works on all fabrics without pre-treatment .

-

What fabrics work best with DTF film ?

Most fabrics! Cotton, polyester, blends, leather, spandex, and activewear ar e all compatible. Stretchable DTF film is ideal for elastic fabrics (e.g., lycra).

-

Do I Need a Special Printer for DTF Film?

Yes. Use a modified inkjet printer (e.g., Epson) with DTF-specific water-based inks. Avoid

regular inkjet or sublimation printers .

-

Are DTF Inks Eco-Friendly?

Many DTF inks are OEKO-TEX® certified and comply with REACH/ZDHC standards,

making them hypoallergenic and low-VOC .

-

Can I Use a Household Iron Instead of a Heat Press?

Yes for small projects. Set to medium heat (no steam), press for 15–20 seconds, and let

cool before peeling. A heat press is recommended for consistency .

-

What’s the Difference Between Hot Peel and Warm Peel Films?

Hot peel: Peel immediately after pressing for a softer feel.

Warm peel: Let cool 10–15 seconds for better edge adhesion .

-

What’s the Best Way to Store DTF Film Long-Term?

Keep unused film in its original sealed packaging or airtight bags. Store flat in a cool, dry

place to prevent curling .

-

How to Handle DTF Film in High-Humidity Environments?

Use a dehumidifier to keep humidity <60%. Excess moisture can cause ink smudging or

powder clumping .

-

What’s the Warranty on DTF Printers and Films?

Our Film warranty is 12 months ..

contact us

contact

Tel: +86 17706217416

Add: Building L2A, No. 520, Lane 1588, Zhuguang Road, Hongqiao World Center, Qingpu District, Shanghai, China