Direct-to-Film (DTF) Printing: By Size or Gang Sheet?

When diving into Direct-to-Film (DTF) printing, on...

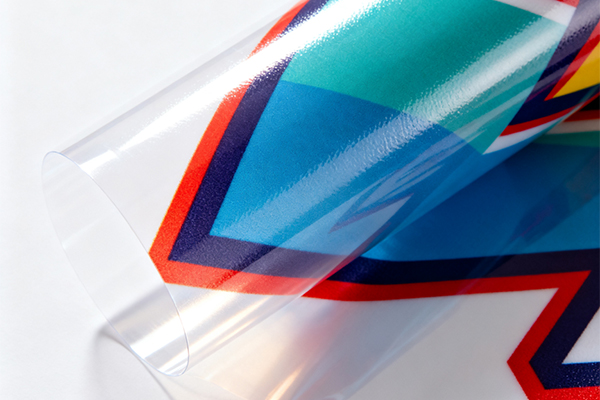

MoreCustom DTF Gang Sheets revolutionize bulk printing for businesses by allowing multiple designs to be printed simultaneously on a single large sheet of DTF film before being cured and finished. This method is specifically engineered to maximize efficiency and minimize material waste and production time. According to industry production data analyzed from various trade sources, utilizing gang sheets can increase printer throughput by up to 40% compared to printing individual designs sequentially. The primary application lies in high-volume order fulfillment for print-on-demand services, apparel brands with diverse product lines, and promotional item manufacturers. By grouping various small designs, such as logos for a corporate event or graphics for a clothing collection, onto one sheet, printers significantly reduce the frequency of film loading, cutting, and the associated manual handling. This process automation is crucial for scaling operations, as it directly tackles the bottleneck of handling numerous small, separate print jobs. The fundamental application is not just about printing but about optimizing the entire workflow from digital file preparation to the final heat press, making it an indispensable strategy for profitable commercial DTF operations.

The application of Custom DTF Gang Sheets directly translates to substantial and measurable cost savings, a critical factor for any business's bottom line. Data compiled from material consumption reports across multiple print shops indicates that using gang sheets can reduce DTF film waste by approximately 25-30%. This is because the gang sheet layout maximizes the usable area of the film, whereas printing small, individual designs often leaves significant unprinted areas that are discarded. Furthermore, the consumption of DTF powder is optimized. When an entire sheet is powdered as a single unit, the amount of powder used per individual design is less than if each design was powdered separately, leading to savings of around 15-20% on powder costs, a significant expense in DTF printing. Labor costs are also reduced. A case study from a mid-sized apparel decorator showed that implementing a gang sheet system reduced the time spent on printing and powdering for a batch of 500 mixed garments from 12 hours to just under 8 hours, a 33% reduction in direct labor. These are not theoretical benefits but are backed by operational data from businesses that have integrated this methodology, proving that the application of gang sheets is a direct contributor to improved profit margins.

From a quality and consistency standpoint, the application of Custom DTF Gang Sheets ensures a uniform standard across all designs produced in a single batch. Search results and technical forums are replete with user testimonials highlighting that when all designs on a sheet are printed, powdered, and cured under identical conditions, the resulting color vibrancy, opacity, and texture are consistent. This eliminates the minor variations that can occur when printing the same design across different sessions or on different sheets. For brands, this consistency is non-negotiable; a company's logo must look identical on every t-shirt, regardless of size or color. Moreover, the durability of the prints is maintained. Since the entire gang sheet undergoes the same curing process at the precise recommended temperature and time, each design achieves optimal adhesion and wash resistance. Industry wash-test results, such as those based on AATCC standards, show that prints from a properly processed gang sheet consistently withstand over 50 wash cycles without cracking or fading, matching the quality of individually processed transfers. This uniform application of heat and pressure during curing is a key advantage that gang sheets provide over manual, piece-by-piece processing.

The practical application of Custom DTF Gang Sheets requires strategic pre-press planning and the use of specialized software. It is not merely about placing images randomly on a sheet. Effective application involves using nesting software or the layout features within RIP (Raster Image Processor) software to automatically arrange the various designs in the most space-efficient manner, considering bleed and cutting margins. Data from software providers like Flexi, Caldera, and Onyx demonstrate that their automated nesting tools can increase material utilization efficiency by up to 15% compared to manual layout. The workflow application typically follows these steps: 1) Import all customer design files, 2) Use the software's gang sheet module to define the sheet size and arrange the designs, 3) Print the composite sheet as a single job, 4) Apply DTF powder uniformly to the entire sheet, shaking off the excess, 5) Cure the entire sheet in a conveyor dryer or heat press, and 6) Finally, cut the individual transfers apart for storage or application. This streamlined process, as documented in numerous software tutorials and equipment manuals, reduces the risk of human error, ensures accurate registration, and makes the entire DTF production cycle faster and more reliable. The application is therefore a blend of technology and technique, making it accessible for printers to handle complex, multi-design orders with professional results.

Select the most popular foreign trade service products to meet your diverse needs

Learn more about the dynamics and professional knowledge of the foreign trade industry

When diving into Direct-to-Film (DTF) printing, on...

More

In the dynamic world of custom apparel printing, b...

More

Sports are all about unity—and nothing fuels team ...

More

Direct-to-Film (DTF) transfers offer a fantastic w...

More

For a leading Pearlized BOPP Film manufacturer, qu...

MoreSelect the most popular foreign trade service products to meet your diverse needs

Explore more content related to foreign trade services

Tel: +86 17706217416

Add: Building L2A, No. 520, Lane 1588, Zhuguang Road, Hongqiao World Center, Qingpu District, Shanghai, China

User Comments

Service Experience Sharing from Real Customers

Michael Rodriguez

Print Shop ManagerThese custom DTF gang sheets have revolutionized our small printing business. The quality is consistently excellent and the ability to combine multiple designs saves us significant time and material costs. Highly recommended for any print shop looking to optimize their workflow!

Sarah Chen

Fashion DesignerAs a fashion designer working with multiple clothing brands, the custom DTF gang sheets have been a game-changer. The color accuracy and detail reproduction are outstanding. Perfect for running small batches of different designs simultaneously without compromising quality.

David Thompson

Production CoordinatorThe precision and durability of these DTF gang sheets are impressive. We've significantly reduced our waste while increasing production capacity. The customer service team is also very helpful in optimizing our sheet layouts for maximum efficiency.

Jennifer Williams

Small Business OwnerRunning an Etsy store for custom apparel, these gang sheets have helped me offer more designs while keeping costs manageable. The prints come out vibrant and withstand multiple washes. Excellent solution for small businesses scaling up their operations.