Applications of BOPP Synthetic Paper in Multiple Fields

-

In-mold labeling

In in-mold labeling , it shines as a preferred choice for plastic containers (such as yogurt cups, detergent bottles, and cosmetic jars): during the molding process, the BOPP synthetic paper label fuses seamlessly with the container’s surface, eliminating the need for adhesives and ensuring a smooth, long-lasting finish that withstands water, oil, and friction—ideal for products requiring robust packaging. For wrap around labels, commonly used on cylindrical containers like soda bottles, juice cartons, and canned goods, BOPP synthetic paper’s flexibility allows it to conform tightly to curved surfaces, while its high opacity ensures vibrant, smudge-proof printing that remains legible even after prolonged handling or exposure to refrigeration. -

PSL (Pressure-Sensitive Label)

In PSL (Pressure-Sensitive Label) facestock, BOPP synthetic paper provides a reliable base for pressure-sensitive adhesives, making it suitable for labels on household cleaners, automotive products, and industrial goods. Its resistance to solvents and extreme temperatures ensures the label stays intact, even in harsh environments. As a direct thermal facestock, it is widely adopted in logistics, retail, and healthcare: the material’s surface is specially treated to react to heat, enabling clear, quick printing of barcodes, shipping labels, and medical records without the need for ink or ribbons, ensuring efficiency and readability in fast-paced settings. -

Advertising Substrate

As an advertising substrate, BOPP synthetic paper excels in outdoor and indoor promotions—from posters and banners to point-of-purchase displays. Its weather resistance (against rain, UV rays, and wind) ensures vibrant graphics remain intact for extended periods, while its lightweight nature makes installation easy. In publications, such as brochures, catalogs, and maps, BOPP synthetic paper offers a durable alternative to traditional paper: it resists wrinkling, tearing, and water damage, making it ideal for travel guides, product manuals, or outdoor activity booklets that need to withstand frequent use and harsh conditions. Whether in labeling or publishing, bopp based synthetic paper delivers a blend of functionality and aesthetics that meets the demands of modern industries.

Become Our Agent

bopp synthetic paper vs traditional synthetic paper

| Aspect | BOPP Synthetic Paper | Traditional Synthetic Paper (PP/PET) |

|---|---|---|

| Base | Biaxially oriented polypropylene | Microporous PP (paper-like) or PET (film-like) |

| Weight/Feel | Lightweight, slick film | PP: paper-like; PET: rigid, premium film |

| Printability | Needs coating; sharp flexo/offset/inkjet | PP: very ink-receptive; PET: high density with coating |

| Opacity/Look | Clear, white, or frosty; “no-label” look possible | PP: high-opacity white; PET: clear or coated white |

| Durability | Tear-resistant; good moisture resistance | PET: best chemical/UV/abrasion; PP: good overall |

| Heat Resistance | Moderate (up to ~80 °C) | PET higher (up to ~120 °C); PP similar to BOPP |

| Dimensional Stability | Good (oriented, low shrink) | PET: excellent; PP: moderate |

| Adhesion/Surfaces | Bonds well to plastics, glass, metal | PET: excels on metals/engineered plastics; PP: versatile |

| Finishing | Easy die-cut; foil/laminate friendly | Works with foil/emboss/laminate; PET needs temp control |

| Cost | Low to mid | PP: mid; PET: mid to higher |

| Recycling | Polypropylene stream (PP) | PP or PET streams, grade-dependent |

| Best Use Cases | Mass-market labels, household, food, “no-label” looks | PP: paper-feel labels/tags; PET: harsh env., long-life labels |

FAQs of BOPP Synthetic Paper in Multiple Fields

-

What key performance requirements must BOPP Advertising Materials Film meet for outdoor use?

BOPP Advertising Materials Film needs excellent weather resistance (resistance to UV rays, rain, and temperature fluctuations) to prevent fading or brittleness. It also requires high transparency or opacity (depending on design needs) and good printability, ensuring vivid ink adhesion for long-term outdoor advertisements.

-

Why is BOPP often chosen as the facestock for labels, and what surface treatment helps improve its performance?

BOPP is preferred for label facestock due to its high tensile strength, dimensional stability, and water resistance (preventing label deformation or damage). To enhance ink/adhesive bonding, it usually undergoes corona treatment to increase surface energy, ensuring durable label application.

-

Can BOPP Wrap-around Labels conform to irregularly shaped containers (e.g., curved bottles), and what property enables this?

Yes. BOPP Wrap-around Labels have good flexibility and elongation (a result of the biaxial stretching process), allowing them to tightly conform to curved or irregular container surfaces without wrinkling. They also maintain shape stability to avoid peeling during storage or use.

-

What makes BOPP suitable for In-mold Labels (IML), and what temperature resistance does it need?

BOPP is ideal for IML because of its heat resistance (withstanding 120–180°C during plastic injection molding) and compatibility with molten resins (e.g., PP, PE). It also has good dimensional stability, ensuring the label integrates seamlessly with the molded product without warping.

-

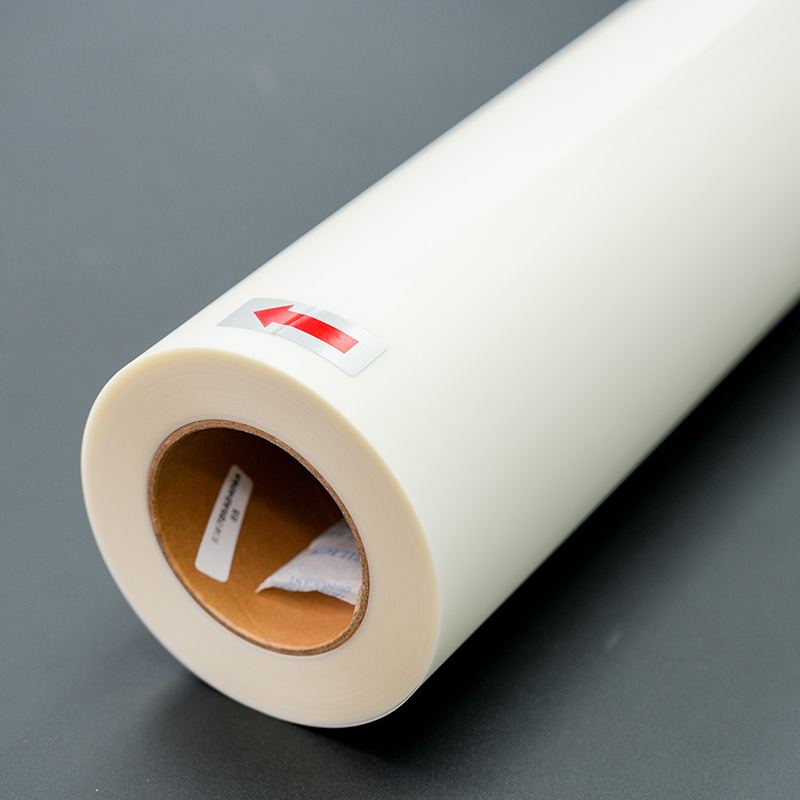

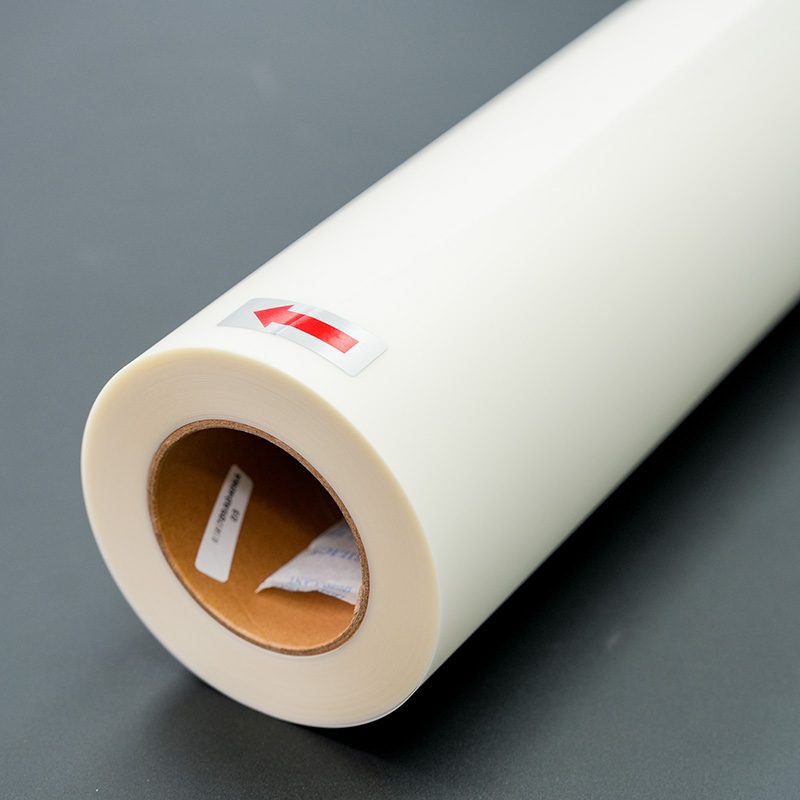

What role does BOPP play in TPU Release Film, and how is its release performance controlled?

In TPU Release Film, BOPP acts as the base layer (providing mechanical support) while coated with a silicone release agent. Its release performance is controlled by adjusting the thickness of the silicone layer and the type of release agent, ensuring TPU films peel off smoothly without residue.

-

How does BOPP Pearlized Film achieve its pearlescent effect, and what applications is it commonly used for?

BOPP Pearlized Film gains its pearlescent effect by adding pearlescent pigments (e.g., mica-based additives) during the film extrusion process, which reflect light to create a soft, iridescent appearance. It is widely us

-

What advantage does BOPP Woven Plastic Matte Laminating Film offer when laminated with woven plastic fabrics?

This film provides matte surface finish (reducing glare) and enhances the woven fabric’s durability—improving its water resistance, scratch resistance, and tensile strength. It also ensures good adhesion to woven plastics, making the composite material suitable for bags, tarps, or outdoor covers.

-

Why is BOPP Courier Bag Laminating Film preferred for courier bag production, and what key strength does it need?

It is preferred for its lightweight nature (reducing shipping costs) and high impact resistance (preventing bag tearing during transit). It typically requires a tensile strength of ≥25 MPa and good puncture resistance to withstand rough handling of courier items.

-

Does BOPP Flower Wrapping Film affect flower freshness, and what design feature addresses this concern?

No, it does not compromise freshness. BOPP Flower Wrapping Film is designed with micro-permeable structures that allow air circulation (maintaining oxygen supply for flowers) while retaining moderate moisture to prevent wilting. It also has high transparency to showcase the flowers’ appearance.

-

What performance requirements must BOPP Building Material Film meet for applications like wall panels or flooring protection?

It needs excellent scratch resistance (to protect building materials during transportation/installation) and chemical resistance (resisting stains from cement, adhesives, or cleaning agents). It also requires good dimensional stability to avoid shrinking/warping under varying temperatures in construction sites.

contact us

contact

Tel: +86 17706217416

Add: Building L2A, No. 520, Lane 1588, Zhuguang Road, Hongqiao World Center, Qingpu District, Shanghai, China