What is DTF

In the dynamic world of fabric printing, the quest...

MoreA single DTF film transfer typically costs between $0.45 and $2.50 per square foot. Material expenses and production methods heavily influence the final dtf film price. The industry's rapid expansion highlights its growing adoption by businesses.

| Metric | Value |

|---|---|

| Market Size in 2023 | USD 2.56 Billion |

| Projected Market Size by 2033 | USD 4.57 Billion |

| Compound Annual Growth Rate (CAGR) (2023-2033) | 5.97% |

Understanding the core material costs is the first step toward accurate pricing and profitability. Three primary consumables drive the per-print expense in DTF production: ink, film, and adhesive powder. Each component has its own cost structure, which businesses must analyze to manage their expenses effectively.

DTF printing utilizes a five-color ink system: Cyan, Magenta, Yellow, and Black (CMYK) plus White. The white ink is crucial. It creates an opaque base layer on the film, ensuring colors appear vibrant and true on dark or colored garments.

Users will find that white ink is often consumed faster and can be more expensive than CMYK inks. This is because it is used Tregs for both the underbase and as a highlight color. The market price for DTF ink varies significantly between suppliers.

Note: The price for a one-liter bottle of white DTF ink can range from under $30 to nearly $80, depending on the brand and quality.

Here is a sample of current market prices for white ink to illustrate this variance:

| Supplier | Ink Type | Price (1 Liter) |

|---|---|---|

| DTF Printer USA | White | $25.95 USD |

| Eagle DTF Print | White | $46.99 USD |

| DTF POWER | White | $78.95 USD |

To put this into perspective, a standard A3-sized print with full coverage consumes approximately 5-7ml of ink. Some estimates break this down further, suggesting a typical A3 design uses about 2 grams of white ink and 2 grams of CMYK ink. Careful monitoring of ink consumption is essential for accurate cost calculation.

The transfer film is the medium that carries the printed design to the garment. It is available in two primary formats: pre-cut sheets and large rolls. The choice between them directly impacts workflow and the overall dtf film price.

Sheets: Best for beginners, small-batch orders, or businesses with desktop-sized printers. They are convenient but have a higher cost per print.

Rolls: Ideal for high-volume production using commercial-grade printers. Rolls offer a significantly lower cost per square foot and enable continuous, automated printing.

Sheet prices are straightforward, with larger sheets offering slightly better value.

| Product | Size (inches) | Current Price per Sheet |

|---|---|---|

| A4 DTF Sheets | 8.27 x 11.69 | $0.75 |

| A3 DTF Sheets | 11.7 x 16.5 | $0.83 |

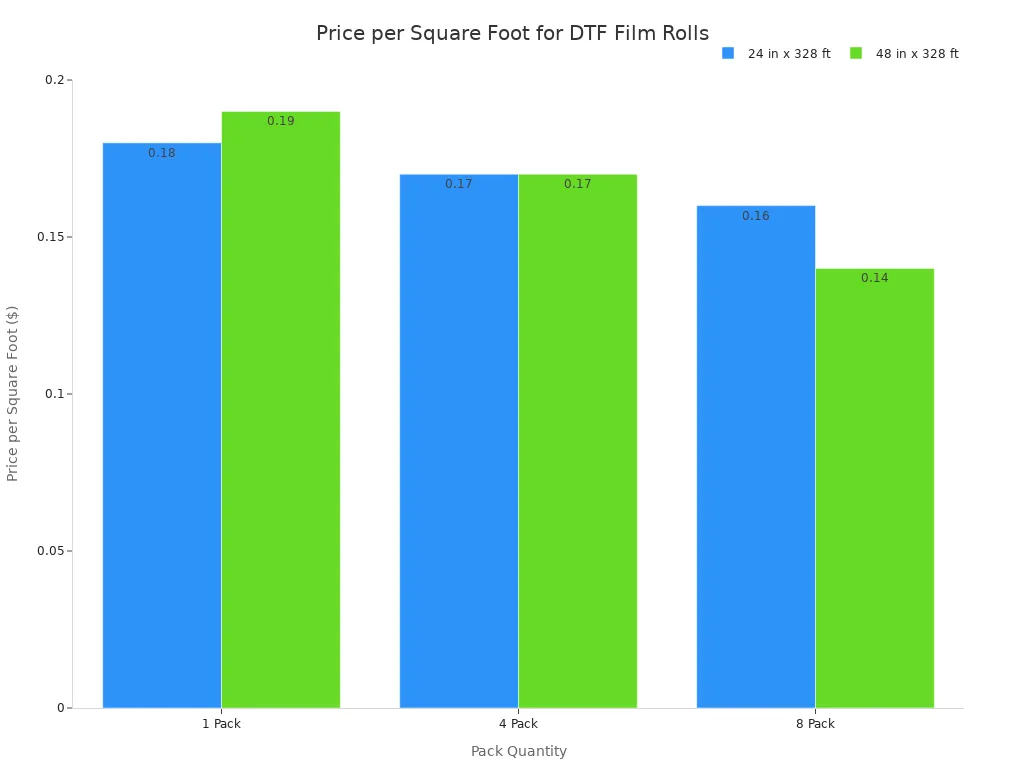

For businesses looking to scale, rolls provide substantial savings. Buying in bulk further reduces the cost. As the data shows, purchasing larger quantities or wider rolls lowers the price per square foot, maximizing material value.

| Roll Size (Width x Length) | Pack Quantity | Price per Square Foot |

|---|---|---|

| 24 in x 328 ft | 1 Pack | $0.18 |

| 24 in x 328 ft | 8 Pack | $0.16 |

| 48 in x 328 ft | 1 Pack | $0.19 |

| 48 in x 328 ft | 8 Pack | $0.14 |

The final key material is the thermoplastic polyurethane (TPU) adhesive powder. After printing, this fine powder is applied to the wet ink on the film. When heated, it melts and forms a durable, flexible adhesive layer. This layer is what bonds the design to the fabric during the heat press stage.

Adhesive powder is typically sold in 1kg (2.2lb) bags. The market price for a 1kg bag of medium-grade powder generally falls between $22.00 and $30.00. The grain size, often around 80-200 microns for a medium powder, affects the final texture and feel of the transfer. A single 1kg bag can cover hundreds of prints, making its per-print cost relatively low, but it remains a necessary expense to factor into every job.

Accurately calculating the cost of each transfer is fundamental to running a profitable DTF business. This calculation moves beyond general estimates to provide a precise material cost for every job. It empowers businesses to set competitive prices and understand their profit margins.

At its core, the material cost for a single DTF print is straightforward. A business can determine its baseline expense by adding the costs of the three primary consumables. This simple formula provides a clear starting point for every print job.

Total Material Cost = Ink Cost + Film Cost + Powder Cost

While this formula is simple, gathering the precise data can be complex. Several online tools exist to help businesses streamline this process. These calculators allow users to input their specific material costs and equipment details to generate accurate estimates.

Inktavo DTF Pricing Calculator: A free spreadsheet that helps users determine profitable pricing.

Tprnt.com Print Cost Calculator: A detailed tool that considers equipment, supplies, and sales volume.

DTFPrinter Gangsheet Calculator: Estimates costs based on design size and helps price various items.

Applying the formula to a real-world scenario clarifies the costs. Let's break down the material expenses for a standard 12x12 inch full-color design printed in-house. This example demonstrates how small individual costs contribute to the final dtf film price.

Film Sheet: Approximately $0.12 to $0.18 per square foot.

Ink (CMYK + White): Around $0.15 to $0.22, depending on design complexity.

Adhesive Powder: Roughly $0.04 to $0.06 per transfer.

Based on these figures, the total material cost for an in-house 12x12 inch print typically falls between $2.00 and $3.00. In contrast, purchasing the same pre-printed transfer from a service provider often costs between $7.00 and $10.00. This highlights the significant savings potential of in-house production.

Deciding between producing transfers in-house and outsourcing to a third-party provider is a critical choice for any apparel decoration business. Each path presents a distinct financial model with unique benefits and drawbacks. A thorough comparison of these models reveals the true cost implications beyond the price of a single transfer.

Bringing DTF production in-house offers maximum control and the lowest per-print material cost. However, this approach requires a significant upfront investment in equipment, including a DTF printer, a powder shaker/curing machine, and a heat press. The expenses do not stop there. Businesses must also account for ongoing operational costs that contribute to the total cost of ownership.

These recurring monthly expenses are essential for accurate financial planning and profitability analysis. A business can expect to budget for several key areas:

Consumables: Ink and film costs can range from $200 to $500 per month, depending heavily on print volume.

Maintenance and Repairs: Setting aside $100 to $200 monthly is wise for routine printhead cleanings and replacing worn parts.

Utilities: Electricity and other overheads can add $50 to $150 to the monthly budget, varying by location and machine usage.

Software: Specialized RIP software often requires a one-time purchase or subscription, sometimes costing between $200 and $500.

Marketing and Packaging: Promoting the business and shipping orders can cost an additional $150 to $700 per month combined.

These operational costs are a permanent part of the in-house production model. They must be factored into every job to ensure pricing covers all expenses and generates a profit.

Outsourcing DTF transfers provides a low-risk entry point into the market. Businesses avoid the large capital investment in equipment and the complexities of maintenance. The primary cost is the price per transfer, which is higher than the material cost of an in-house print. This model is ideal for startups, businesses with fluctuating order volumes, or those testing new designs.

While the per-unit cost is higher, suppliers often provide incentives for larger orders. Buying in bulk significantly reduces the per-unit price, making outsourced transfers more affordable without sacrificing quality. This scalable pricing structure allows a business to grow its profit margins as its order volume increases.

Many suppliers begin offering bulk discounts on orders of 10+ sheets or once a specific dollar amount is reached.

This approach simplifies the overall dtf film price calculation for a business. The cost is a straightforward transaction with the supplier, eliminating the need to track ink consumption, maintenance schedules, or wasted materials. It transforms a complex production expense into a predictable cost of goods sold, allowing business owners to focus on design, marketing, and sales.

Choosing the right printing technology depends heavily on cost, volume, and design complexity. A business can optimize its profitability by comparing the dtf film price and process against established methods like Direct-to-Garment (DTG) and screen printing.

DTF and DTG both excel at producing full-color, detailed designs, but their cost structures differ significantly. DTG printing applies ink directly to the fabric, which requires pre-treatment for dark garments, increasing costs. DTF, in contrast, prints on a universal film, making it versatile across all fabric types and colors.

For a single print, DTG can be cheaper on white shirts, but its price rises sharply on dark apparel due to the need for a white ink underbase. DTF maintains a more consistent cost per print.

| Printing Method | Garment Color | Average Cost Per Print |

|---|---|---|

| DTG | White/Light | $0.50 - $1.00 |

| DTG | Dark | $1.25 - $3.50 |

| DTF | Any Color | $1.50 - $2.10 |

Note: DTF is often more efficient for small to medium-sized runs. Its process is generally faster than DTG for multiple items, which can lower labor costs and improve turnaround times.

Screen printing is the industry standard for high-volume orders. However, it involves significant setup costs, as a separate screen must be created for each color in a design. This makes it expensive for small batches or multi-color jobs.

DTF eliminates these setup costs, making it far more economical for small to medium-sized orders. For a small batch of 50 shirts, DTF offers substantial savings over screen printing.

| Printing Method (50 Shirts) | Cost Per Piece |

|---|---|

| DTF | $1.05 - $1.95 |

| Screen Printing | $1.50 - $2.80 |

| Savings with DTF | 20-40% |

This advantage diminishes as order volume increases. Screen printing becomes more cost-effective for large batches, typically when an order quantity exceeds 100 shirts. At that point, the efficiency of bulk production outweighs the initial setup expenses.

Beyond the initial purchase of a printer, several hidden costs can impact profitability. Businesses must account for these ongoing expenses to calculate the true dtf film price and maintain healthy margins. These costs often fall into three main categories: maintenance, material waste, and workspace setup.

DTF printers require regular maintenance to perform reliably. Neglecting this upkeep leads to poor print quality and costly downtime. A proactive maintenance budget is essential for any in-house production. Annual expenses can add up quickly.

Printhead Replacement: $300 to $1,500 every 6–12 months.

General Maintenance: $50 to $200 per month for cleaning kits and fluids.

Annual Service: $500 to $2,000 for professional calibration.

Setting aside a budget of $1,000 to $5,000 annually helps keep equipment in top condition and minimizes unexpected repair bills.

Every misprint consumes valuable ink, film, and powder, directly increasing operational costs. Production errors are inevitable, but understanding their causes can reduce waste. Common issues include:

Poor Adhesion: The design fails to stick due to an improperly cured film.

Ink Cracking: The print cracks after transfer from over-curing or excessive pressure.

Clogged Printheads: Dried ink inside nozzles causes streaks and missing lines.

Film Wrinkling: Uneven heat or tension distorts the final transfer.

Careful calibration and operator training are key to minimizing these expensive mistakes.

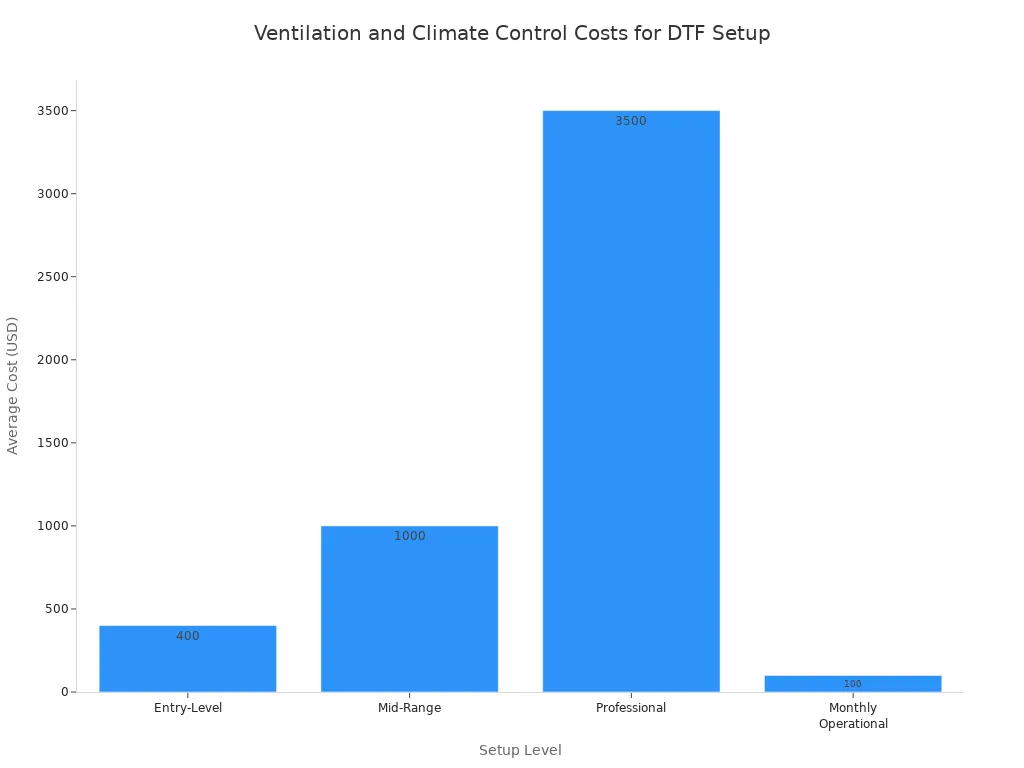

DTF technology is sensitive to its environment. The printing area requires stable climate control to ensure consistent results. For optimal performance, a business should maintain a temperature between 68 to 77°F (20 to 25°C) and a relative humidity of 40% to 60%.

Achieving these conditions involves costs for ventilation and air filtration to manage fumes and airborne powder. The investment varies based on the scale of the operation.

These environmental systems are not just a recommendation; they are a necessary expense for quality and safety.

Moving beyond material costs is essential for building a sustainable business. A profitable pricing strategy must account for labor, overhead, and production efficiency. Mastering these elements allows a business to set competitive prices that cover all expenses and secure healthy profit margins.

Labor is a significant operational cost that directly impacts the final price of a DTF product. Businesses must calculate this expense accurately, whether producing in-house or outsourcing.

For in-house operations, labor costs are integrated into the overall operational budget.

When outsourcing transfers, a business may face an additional labor charge for application, often ranging from $0.12 to $0.18 per shirt.

Printing in batches is an effective strategy to reduce labor time and its associated costs.

Beyond labor, overhead expenses like rent, utilities, and software subscriptions contribute to the total cost of doing business. These fixed costs must be factored into the price of every item sold to ensure long-term profitability.

Using gang sheets is a powerful technique to lower the dtf film price per image. This method involves arranging multiple designs onto a single large film sheet, which optimizes material use and print time. Combining designs reduces the need for multiple print runs and minimizes wasted film, making it a cost-effective solution for bulk orders.

Strategic layout is key to maximizing a gang sheet's value. Businesses can use several methods to arrange designs efficiently.

| Layout Strategy | Ideal Use Case |

|---|---|

| Grid Alignment | Large orders of the same uniformly sized graphic |

| Color Block Grouping | Designs with similar dominant color palettes |

| Nesting Designs | Fitting smaller designs into gaps around larger ones |

The nesting technique is particularly effective. One shop reported a 22% reduction in film usage by tucking smaller icons and logos into the empty spaces around larger graphics.

This optimization saves money on materials and accelerates order delivery by making each print cycle more productive.

A business's final DTF cost reflects its material expenses and production choices. Outsourcing offers a low-risk entry for beginners to understand the market. In-house producers must calculate the total cost of ownership beyond the initial printer price. Mastering cost calculation is the first step toward running a profitable DTF business.

White ink is typically the most expensive consumable. Businesses use it heavily for the underbase on dark garments, which increases consumption and overall ink costs for those jobs.

DTF printing offers strong profit potential. Small businesses can maximize profitability by managing material costs, minimizing waste, and using gang sheets to lower the per-print expense.

Outsourcing is often better for beginners. This approach avoids large equipment investments. It allows a new business to test the market with minimal financial risk before scaling up.

Select the most popular foreign trade service products to meet your diverse needs

Learn more about the dynamics and professional knowledge of the foreign trade industry

Select the most popular foreign trade service products to meet your diverse needs

Explore more content related to foreign trade services

Tel: +86 17706217416

Add: Building L2A, No. 520, Lane 1588, Zhuguang Road, Hongqiao World Center, Qingpu District, Shanghai, China

User Comments

Service Experience Sharing from Real Customers

Michael Rodriguez

Graphic DesignerThe DTF film price is incredibly competitive for the quality. Our print shop has significantly reduced costs while achieving vibrant, durable transfers. Excellent value!

Sarah Chen

Production ManagerAs a small business owner, finding affordable DTF film was crucial. The price point here is fair, and the film consistency is reliable. Great balance of cost and performance.

David Kim

Operations DirectorOutstanding price-to-quality ratio. We compared multiple suppliers, and this DTF film offers the best price without compromising on transfer detail or fabric adhesion. Highly recommended.

Jessica Williams

Studio OwnerThe transparent pricing and bulk discounts made scaling our DTF operations feasible. The film's performance at this price is unmatched—our go-to supplier now.