DTF Film vs Heat Transfer Vinyl (HTV): Which Is Better for Your Garment Business?

If you run a garment business, you’ve probably deb...

MoreA glossy dtf film delivers vibrant, eye-catching colors with a shiny, smooth finish. In contrast, matte film offers a subtle, premium appearance. Its soft, non-reflective quality creates a design that feels integrated with the fabric, providing a distinguished, high-end look for apparel decorators.

The first impression a custom t-shirt makes is visual. The choice between a glossy and matte finish directly influences how a design is perceived, from its color intensity to its overall aesthetic. Each finish offers distinct advantages depending on the desired outcome.

A glossy dtf film provides a vibrant, high-impact finish. Its smooth, reflective surface acts like a varnish, making colors appear deeper, richer, and more saturated. This effect is particularly noticeable with bright hues and complex, photorealistic images. The light reflects off the design, immediately drawing the eye and creating a powerful visual statement.

This finish is the top choice for designs that need to command attention. Consider these applications:

Promotional Apparel: Bold logos and event graphics pop, ensuring maximum brand visibility.

Youth and Streetwear Brands: Designs with vibrant colors and intricate details appear sharp and energetic.

Photographic Prints: The glossy surface enhances contrast and depth, making photos look crisp and lifelike on fabric.

Note: The high shine of a glossy dtf film can create a distinct separation between the design and the fabric. This "sticker-like" appearance is often a deliberate stylistic choice for modern, graphic-heavy apparel.

Matte film offers a sophisticated, non-reflective finish. It absorbs light rather than reflecting it, which gives the design a soft, muted appearance. This quality allows the artwork to look and feel more integrated with the t-shirt fabric, resulting in a subtle and high-end aesthetic. Brands aiming for an elegant or minimalist style often prefer this understated look.

The absence of shine also provides a practical benefit in various lighting conditions. Matte film excels at reducing glare, making the design easy to view from any angle.

Its textured surface diffuses light, preventing harsh reflections in direct sunlight or under bright indoor lights.

It scatters light evenly, which improves readability and viewer comfort.

In contrast, a glossy dtf film can produce a distracting glare that obscures details in bright environments.

This makes matte film an excellent choice for retail apparel, corporate branding, and any design where a premium, "in-the-fabric" feel is paramount.

A transfer's feel, often called its "hand," significantly impacts the final garment's quality and comfort. The texture of a DTF print can range from a slick, noticeable layer to a soft, barely-there finish, depending entirely on the film choice.

Glossy transfers create a distinct, smooth surface on the t-shirt. The hand is noticeably slick and has a plastic-like quality, sitting on top of the fabric rather than blending into it. This texture is a direct result of the film's reflective properties. While this creates exceptional visual pop, the wearer will always feel the design as a separate layer on the garment. This pronounced feel is often suitable for outerwear, jerseys, or promotional items where a durable, slick graphic is part of the style.

Matte transfers offer a superior soft-hand feel that many premium apparel brands demand. The finish integrates into the fabric's weave, resulting in a texture that is much less noticeable to the touch. This creates a comfortable, high-end product that feels lightweight and breathable.

Pro Tip: Decorators can further enhance the soft feel and breathability of matte prints. Certain techniques help avoid a thick, heavy application and improve wearer comfort.

Using a black knockout halftone effect makes the print lighter.

Reducing the overall ink density contributes directly to a softer feel.

Choosing a matte finish inherently avoids the thick, plasticky texture common with glossy alternatives.

This focus on a minimal hand makes matte film the ideal choice for fashion-forward brands, boutique shops, and any garment where comfort is a top priority.

A design's longevity is as crucial as its initial appearance. Both glossy and matte DTF films offer excellent durability, but they protect the print in different ways. Understanding these differences helps decorators choose a film that aligns with the garment's intended use and lifespan.

Glossy film excels at preserving color vibrancy through repeated washing. The shiny topcoat acts as a protective shield for the ink layer underneath, locking in color and preventing it from dulling over time. This robust protection is verified through industry-standard testing.

Professional Standard: High-quality transfers are evaluated using tests like AATCC 61 for colorfastness. A properly cured glossy print can achieve a top rating of 4 or 5, indicating minimal color loss after dozens of washes.

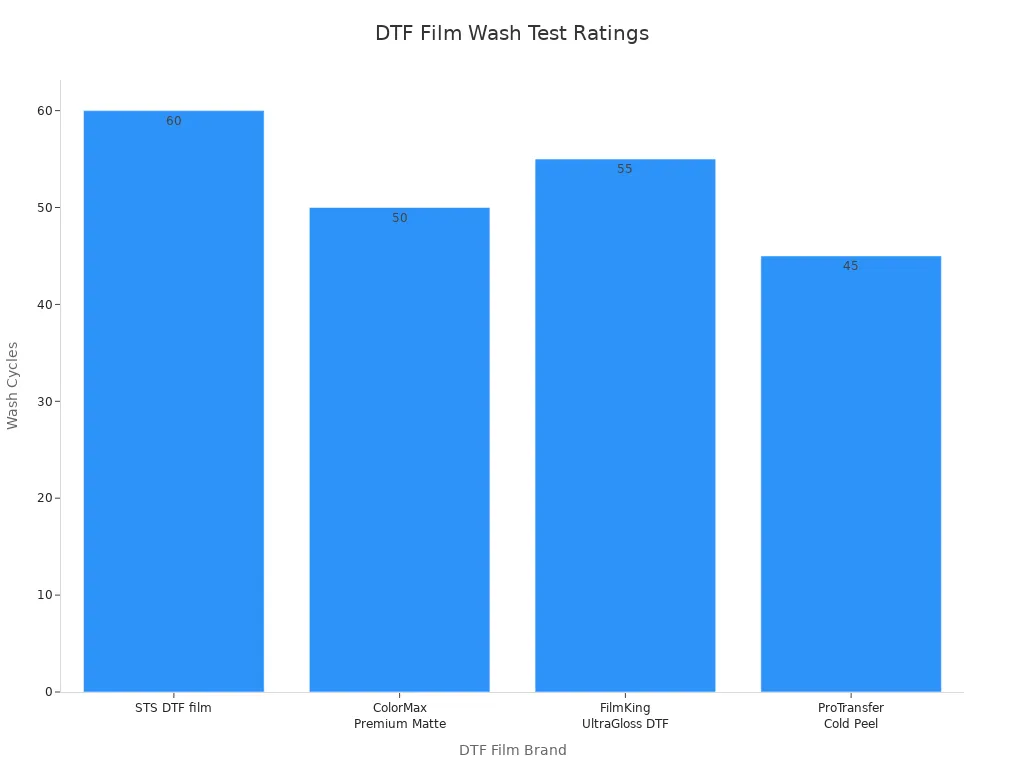

This durability makes glossy film a reliable choice for long-lasting, vibrant designs. Wash test data from various brands confirms this performance.

Matte film offers superior flexibility, making it highly resistant to cracking and peeling. Because the finish integrates more deeply into the fabric, it can stretch and move with the garment without breaking. This quality is essential for apparel that endures frequent wear and movement.

Case studies demonstrate the impressive resilience of this finish. In multiple wash tests, DTF transfers showed no signs of cracking after more than 45 wash cycles. This elasticity ensures the design remains intact and smooth, preserving the premium quality of the garment. This makes matte film an ideal solution for everyday fashion, athletic apparel, and any item where flexibility and long-term wear are paramount.

Applying a glossy dtf film requires precision, as the process directly impacts the final transfer's quality and appearance. Most glossy films are designed for a "hot peel" method, which demands specific timing and technique for optimal results. This process is faster than cold peeling but has a steeper learning curve.

The term "hot peel" means the operator must remove the film carrier sheet immediately after the heat press opens, while the design is still hot. This quick action allows the ink to release onto the garment, creating a vibrant finish. The process offers a significant time advantage, making it ideal for high-volume production runs. However, this speed requires accuracy. If an operator waits too long and the transfer cools, the design may not release completely from the film, leading to a failed application. The timing is critical for achieving a clean, sharp transfer without cracks or imperfections.

Achieving a flawless glossy application becomes consistent with the right technique. Professionals follow key steps to ensure success and maximize the film's visual impact.

Verify Press Settings: Always confirm your heat press is at the manufacturer's recommended temperature and pressure. Inconsistent heat is a primary cause of transfer failure.

Peel with Confidence: Once the press cycle is complete, peel the film back in one smooth, swift motion. Hesitation can cause the transfer to cool unevenly.

Use a Consistent Angle: Peel the film at a low, consistent angle rather than pulling straight up. This reduces stress on the fresh print.

Pro Tip: For enhanced durability and a softer feel, perform a second press. After peeling the film, cover the design with parchment or a Teflon sheet and press again for 5-10 seconds. This helps lock the design into the fabric fibers.

Matte DTF film simplifies the application process, making it a more forgiving and reliable option for decorators of all skill levels. Its "cold peel" nature provides a larger margin for error and contributes to a more consistent, high-quality final product. This ease of use is a key reason many print shops prefer it for daily production.

The term "cold peel" defines the application method for most matte films. The operator presses the design and then allows the transfer to cool down completely before removing the film carrier. This process eliminates the urgency required for hot peel films, offering several distinct benefits.

Wider Time Window: Operators do not need to peel the film immediately. They can set the garment aside to cool, which is ideal for batch processing multiple items.

Increased Consistency: The cooling period allows the ink and adhesive to set properly, ensuring a uniform and complete transfer every time.

Beginner-Friendly: New users can learn the process quickly without the stress of precise, split-second timing.

This methodical approach builds confidence and reduces wasted materials.

The deliberate nature of the cold peel process inherently minimizes common application mistakes. Waiting for the transfer to cool ensures the adhesive has fully bonded to the t-shirt fibers. This secure bond prevents partial transfers, where parts of the design stick to the film instead of the garment. The film also remains stable during cooling, which prevents the design from stretching or distorting during the peel.

Key Takeaway: The stability of matte film during the cooling and peeling phase is crucial. It ensures fine details and text remain crisp and intact, which is a common challenge with the immediate, high-heat removal of hot peel films. This reliability makes matte film a go-to choice for intricate or detailed artwork.

The final decision rests on the design's objective. A glossy dtf film achieves maximum vibrancy for bold graphics. Matte film provides a premium, soft feel for high-end apparel.

Consider the End-User: A youth brand may prefer a shiny finish, while a boutique often selects a subtle matte look.

Test Your Designs: We recommend decorators test both film types to confirm which best fits their brand and customer expectations.

Decorators prefer matte film for athletic apparel. Its superior flexibility allows the design to stretch with the fabric. This quality significantly reduces the risk of cracking during intense physical activity.

Yes, combining finishes is an advanced technique. Applying both glossy and matte transfers to a single garment creates a unique design with contrasting textures, adding visual depth and a custom feel.

Both films work well on any color. Glossy film enhances vibrancy on all fabrics. Matte film provides a subtle, integrated look on both light and dark shirts for a premium appearance.

Select the most popular foreign trade service products to meet your diverse needs

Learn more about the dynamics and professional knowledge of the foreign trade industry

If you run a garment business, you’ve probably deb...

MoreIn the dynamic world of custom apparel printing, b...

MoreOutdoor graphic materials face constant exposure t...

MoreSelect the most popular foreign trade service products to meet your diverse needs

Explore more content related to foreign trade services

Tel: +86 17706217416

Add: Building L2A, No. 520, Lane 1588, Zhuguang Road, Hongqiao World Center, Qingpu District, Shanghai, China

User Comments

Service Experience Sharing from Real Customers

Michael Chen

Print Shop OwnerThe glossy DTF film produces incredibly vibrant and durable prints. The colors really pop on dark garments, and the transfer process is consistently reliable. A game-changer for our custom apparel business.

Sarah Johnson

Graphic DesignerAs a designer, color accuracy and finish are everything. This glossy film delivers exceptional detail and a professional, high-end shine that my clients love. It's now my go-to for all premium projects.

David Rodriguez

Production ManagerExcellent film for high-volume orders. The glossy finish adds great value, and the film feeds through our printers without jamming. Consistent quality that has significantly reduced our waste rate.

Lisa Wang

Small Business OwnerStarting my own t-shirt line was daunting, but this glossy DTF film made it so much easier. The prints are wash-resistant and have a beautiful, professional sheen. Customer feedback on the print quality has been overwhelmingly positive.