The Pros and Cons of DTF film printing: A Comprehensive Guide

In the dynamic world of custom apparel printing, b...

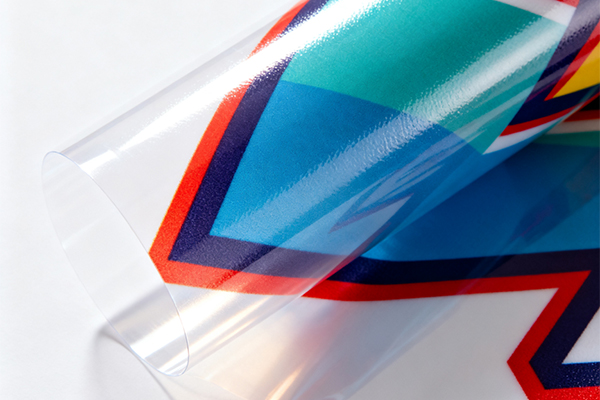

MoreThe application of DTF print paper represents a significant advancement in the textile printing industry, offering unparalleled versatility and quality for custom apparel and merchandise. This technology enables the transfer of intricate, full-color designs onto a vast array of fabrics, including cotton, polyester, blends, and even some non-textile surfaces, with exceptional durability and a soft hand feel. The core of the process involves printing a design onto a special PET film, applying a hot-melt adhesive powder, and then using a heat press to permanently fuse the design onto the substrate. This method has rapidly gained market share, positioning itself as a formidable competitor to traditional DTG (Direct-to-Garment) and sublimation printing, particularly for its ability to print on dark garments and a wider range of materials without pre-treatment. The global DTF film market is a testament to this growth, with industry reports from firms like Grand View Research projecting its value to reach into the billions of dollars within the current decade, driven by rising demand from the fashion, sportswear, and promotional product industries. Its application is revolutionizing how small businesses, large print shops, and designers approach custom printing, making high-quality, photorealistic prints more accessible and cost-effective than ever before.

The application of DTF print paper excels in several key areas that directly impact print quality and business operations. First and foremost is its superior color vibrancy and opacity. Unlike DTG printing, which can struggle with color brilliance on dark garments without a white underbase, DTF inherently prints a white layer as part of the process. This results in exceptionally bright and opaque colors on any color fabric, a fact consistently highlighted in user reviews and comparative analyses on platforms like YouTube and printing forums. Search data and industry case studies show that this capability is a primary driver for shops switching from DTG to DTF for their dark garment production. Secondly, the durability of DTF prints is a major selling point. The adhesive layer creates a strong bond with the fabric fibers, resulting in prints that are highly resistant to cracking, peeling, and washing. Independent wash-test results, often cited in industry publications, demonstrate that DTF prints can withstand 50+ industrial wash cycles while maintaining their integrity, meeting the stringent standards for sportswear and workwear. Furthermore, the application process is remarkably fabric-agnostic. While DTG is primarily for cotton and sublimation for polyester, DTF can be successfully applied to cotton, polyester, nylon, silk, leather, and even denim with minimal adjustment, providing businesses with unprecedented flexibility to expand their product offerings without investing in multiple printing technologies.

From an economic and operational standpoint, the application of DTF print paper offers compelling advantages that align with search queries for "profitable printing business" and "low-cost custom apparel." The startup cost for a DTF operation is significantly lower than that for an automated DTG setup with a pretreatment machine. A basic DTF system, comprising a modified printer, a powder shaker, and a heat press, represents a manageable investment for startups and small businesses, a point frequently emphasized in equipment reviews on e-commerce platforms like Amazon and AliExpress. Operational costs are also competitive. While the consumables (film and adhesive powder) have a per-print cost, the reduction in labor, elimination of pretreatment steps, and near-zero waste from no-need-to-print white underbase layers on light garments contribute to a favorable overall cost-per-print. Data aggregated from various print shop owners in online communities suggests that for mixed batches of light and dark garments, DTF can be more cost-effective than DTG. Moreover, the process is less prone to operator error. There is no clogging of print heads from white ink, a common and costly issue in DTG, which leads to higher productivity and less downtime. This reliability makes it an ideal solution for fulfilling large orders consistently and profitably.

The future application of DTF print paper is poised for further expansion, with ongoing innovations addressing its initial limitations. Current research and development, as seen in product releases from major consumable suppliers, are focused on enhancing the softness of the print finish to rival that of DTG, developing low-temperature adhesives for heat-sensitive materials like nylon and spandex, and creating more eco-friendly adhesive powders. Search trends indicate a growing interest in "soft DTF" and "eco-friendly DTF," signaling market demand for these improvements. The technology is also expanding beyond apparel into new markets such as customized footwear, caps, bags, and home textiles, with successful case studies being shared by early adopters on social media and trade shows. As the supply chain for DTF materials becomes more robust and competitive, prices for films and powders are expected to decrease further, solidifying DTF's position as a dominant digital printing method. Its ability to combine the strengths of other technologies—the color vibrancy of sublimation, the fabric range of vinyl, and the digital flexibility of DTG—into a single, efficient process ensures that the application of DTF print paper will continue to shape the future of on-demand and customized manufacturing for years to come.

Select the most popular foreign trade service products to meet your diverse needs

Learn more about the dynamics and professional knowledge of the foreign trade industry

In the dynamic world of custom apparel printing, b...

More

Flexo printing uses flexible plates to create high...

More

Direct-to-Film (DTF) transfers offer a fantastic w...

More

When it comes to transferring designs onto objects...

More

When diving into Direct-to-Film (DTF) printing, on...

More

Select the most popular foreign trade service products to meet your diverse needs

Explore more content related to foreign trade services

Tel: +86 17706217416

Add: Building L2A, No. 520, Lane 1588, Zhuguang Road, Hongqiao World Center, Qingpu District, Shanghai, China

User Comments

Service Experience Sharing from Real Customers

Michael Rodriguez

Graphic DesignerThis DTF print paper is exceptional! The color vibrancy and detail reproduction on fabrics are outstanding. It has significantly improved the quality of our custom apparel line. Highly recommended for any professional printing needs.

Sarah Chen

Print Shop ManagerAfter testing multiple DTF papers, this one stands out for its consistent performance and excellent adhesive properties. The transfer process is smooth and the results are durable. Our customers have noticed the quality improvement immediately.

David Thompson

Textile EngineerVery impressed with the paper's performance on various fabric types. The white ink coverage is excellent and the flexibility after washing meets industry standards. Minor curling issues but overall a great product for professional use.

Jennifer Williams

Small Business OwnerThis DTF paper has revolutionized our custom t-shirt business! The ease of use and professional results have helped us expand our product offerings. The colors stay bright even after multiple washes. Absolutely love this product!