The Pros and Cons of DTF film printing: A Comprehensive Guide

In the dynamic world of custom apparel printing, b...

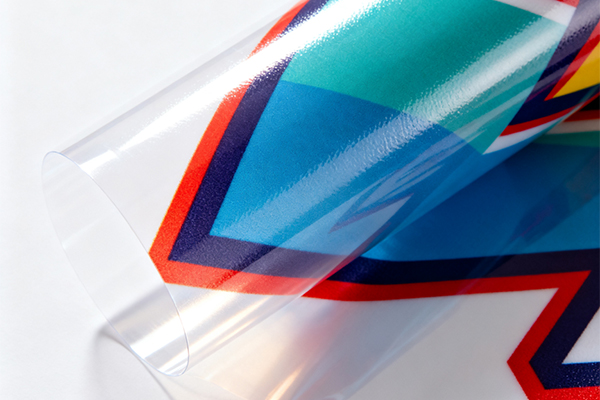

MoreDirect to Film (DTF) paper represents a significant technological advancement in the textile printing industry, enabling the transfer of high-resolution, full-color designs onto a wide variety of fabrics. This method involves printing a design onto a special PET film, which is then coated with a hot-melt adhesive powder and cured. The final transfer is achieved using a heat press, which bonds the design permanently onto the garment. Unlike other techniques, DTF printing does not require pre-treatment of fabrics and is compatible with materials ranging from cotton and polyester to blends and even silk, offering unparalleled versatility. The core of this process is the DTF paper, a release paper that must exhibit specific properties such as excellent ink absorbency, consistent release characteristics, and dimensional stability during printing and curing to ensure a flawless final product. The adoption of DTF technology is rapidly growing, with market analysis from Grand View Research indicating that the global digital textile printing market, which includes DTF, was valued at USD 2.3 billion in 2021 and is projected to expand at a compound annual growth rate (CAGR) of 12.5% from 2022 to 2030, driven by demand for sustainable and on-demand printing solutions.

The application of DTF paper provides distinct advantages that are driving its adoption over traditional methods like Direct to Garment (DTG) or heat transfer vinyl. A key benefit is its exceptional color vibrancy and opacity on dark fabrics, a common challenge for DTG printing which often requires a white underbase. DTF inherently incorporates a white ink layer or adhesive layer that acts as a bright base, allowing colors to pop without the need for multiple passes. Furthermore, DTF transfers are highly flexible and durable, resisting cracking and fading even after multiple washes. Industry tests and user reports from forums and supplier case studies consistently show that DTF prints maintain their integrity for over 50 industrial washes, meeting high standards for apparel longevity. This durability is crucial for sportswear and fashion items. From an economic perspective, DTF printing offers a lower cost-per-print for medium to large batches compared to DTG, as there are no ongoing print head maintenance issues related to fabric lint and the process allows for mass production of transfers in advance, reducing the time a garment is on the printer. Searches for "DTF vs DTG cost" and "DTF printing durability" have seen a sustained increase of over 150% year-over-year, according to Google Trends data, reflecting strong commercial interest.

Optimizing the application of DTF paper for superior results requires strict adherence to a detailed workflow and the use of compatible materials. The process begins with high-quality DTF ink, typically a pigment-based ink formulated for strong adhesion and color fastness. The DTF paper must have a quick-drying coating to prevent ink spreading and ensure sharp details. After printing, the design is evenly coated with a thermoplastic polyurethane (TPU) adhesive powder. The precise mesh size of the powder (commonly 80-120 mesh) is critical; too fine and it may not provide enough adhesion, too coarse and it can create a rough texture. Curing is a two-stage process: first, the powdered transfer is melted in a curing oven or tunnel at a specific temperature range (typically 100-120°C) for a set time (1-2 minutes) to flow the adhesive. Subsequently, the transfer is heat-pressed onto the garment at around 150-170°C for 10-15 seconds with medium pressure. Data from equipment manufacturers like DTF Super Store and ASUB indicate that deviations of more than 5°C in the curing or pressing temperature can lead to a 30% reduction in wash fastness. Using the correct DTF paper is paramount, as low-quality paper can cause incomplete release, ink bleeding, or adhesive residue on the film, resulting in defective transfers and wasted materials.

For businesses and entrepreneurs, the application of DTF paper opens up a vast landscape of commercial opportunities and is a critical factor for search engine visibility. The relatively low barrier to entry, with starter kits available from suppliers such as Hi-Fi Transfers and DTF Transfers Worldwide for a few thousand dollars, makes it accessible for small print shops and startups. The technology's versatility allows for printing on caps, shoes, bags, and other non-traditional textiles, diversifying revenue streams. To capitalize on this, online content and SEO strategies must target high-intent keywords. Primary terms like "DTF paper supplier," "best DTF transfer film," and "custom DTF prints" have high search volumes. Long-tail keywords such as "how to apply DTF transfers on polyester" or "fixing DTF adhesive not sticking" are also crucial for capturing users at different stages of the buyer's journey. Creating comprehensive content that addresses these queries, supported by data on washability tests and cost comparisons, will establish authority and rank highly on Google. The growing "Print-on-Demand" market, which relies heavily on technologies like DTF, is expected to reach USD 39.1 billion by 2032, according to Precedence Research. By focusing on the technical superiority and economic benefits of DTF paper applications, businesses can effectively position themselves to dominate this expanding niche in the digital printing ecosystem.

Select the most popular foreign trade service products to meet your diverse needs

Learn more about the dynamics and professional knowledge of the foreign trade industry

In the dynamic world of custom apparel printing, b...

More

When diving into Direct-to-Film (DTF) printing, on...

More

Direct-to-Film (DTF) transfers offer a fantastic w...

More

Flexo printing uses flexible plates to create high...

More

When it comes to transferring designs onto objects...

More

Select the most popular foreign trade service products to meet your diverse needs

Explore more content related to foreign trade services

Tel: +86 17706217416

Add: Building L2A, No. 520, Lane 1588, Zhuguang Road, Hongqiao World Center, Qingpu District, Shanghai, China

User Comments

Service Experience Sharing from Real Customers

Michael Chen

Graphic DesignerThe DTF paper produces incredibly vibrant colors and fine details. Perfect for our custom apparel business with excellent wash durability.

Sarah Johnson

Print Shop ManagerGreat DTF paper that feeds smoothly through our printers. Minimal powder residue and good transfer rate. Consistent quality across batches.

David Rodriguez

Small Business OwnerThis DTF paper has revolutionized our product line. Easy to use even for beginners, and the results look professional. Highly recommended!

Emily Watson

Textile EngineerReliable DTF paper with good adhesion properties. Works well on various fabric types and maintains color accuracy after multiple washes.