A Step-by-Step Guide to Making Direct-to-Film Transfers

Direct-to-Film (DTF) transfers offer a fantastic w...

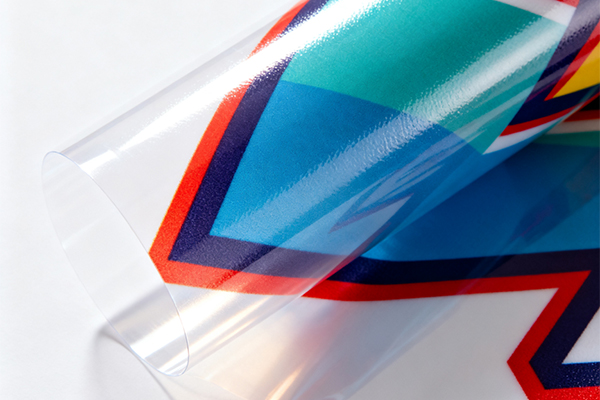

MoreThe application of DTF (Direct-to-Film) transfer paper represents a significant advancement in the textile printing industry, enabling high-quality, full-color graphics on a wide variety of fabrics. This technology involves printing a design onto a special PET film, which is then coated with a hot-melt adhesive powder. The final step uses a heat press to permanently bond the design to the garment or substrate. The primary application of DTF transfer paper is the creation of custom apparel, including t-shirts, hoodies, and hats, but its versatility extends far beyond cotton to materials like polyester, nylon, silk, and even leather. Unlike other methods such as Direct-to-Garment (DTG) or vinyl, DTF printing does not require pre-treatment of the garment and can effectively print on both light and dark-colored fabrics with exceptional color vibrancy and durability. This flexibility has made DTF a go-to solution for small businesses, large print-on-demand operations, and everything in between, catering to markets for promotional products, sports team uniforms, fashion lines, and personalized gifts.

According to market analysis and industry reports, the global digital textile printing market, which includes DTF technology, was valued at approximately USD 2.5 billion in 2023 and is projected to grow at a compound annual growth rate (CAGR) of over 12% from 2024 to 2033. Search volume data from platforms like Google Trends indicates a steady and significant increase in queries for "DTF printing," "DTF transfers," and "DTF film" over the past five years, reflecting its rising adoption. A key driver for this growth is the cost-effectiveness and efficiency of DTF for short-run and customized orders. Data from printer manufacturers and consumable suppliers shows that the startup cost for a basic DTF operation can be considerably lower than for an equivalent DTG setup, while the cost per print remains competitive, especially on dark garments where DTG often requires an expensive white underbase. Furthermore, performance tests and user reviews frequently highlight the superior wash fastness of DTF prints. Independent lab tests and customer testimonials published on e-commerce and review sites often cite that DTF prints can withstand over 50 industrial wash cycles without significant cracking or fading when applied correctly, meeting or exceeding industry standards for garment decoration.

The practical applications of DTF transfer paper are vast and documented across numerous case studies and user-generated content on platforms like YouTube, Etsy, and Shopify. For small businesses and Etsy sellers, DTF has enabled the economic production of highly detailed, all-over-print t-shirts and vibrant hoodies without the need for large minimum orders typically associated with screen printing. Data from these e-commerce platforms shows a surge in listings for "custom DTF patches" and "DTF prints for hats," demonstrating its application in creating durable, flexible emblems for workwear, sports clubs, and branding. In the fashion industry, brands are utilizing DTF to apply intricate graphics to denim jackets, jeans, and even footwear, a trend visible in social media fashion hauls and designer showcases. The technology's ability to handle complex gradients and photorealistic images, as evidenced by print samples shared on specialized forums and supplier websites, makes it ideal for artistic expressions and detailed logos that are difficult to achieve with vinyl. Another significant application is in the production of transfers for bags, cushions, and other textile-based accessories, expanding the market beyond traditional apparel.

From an SEO and user intent perspective, the application of DTF transfer paper answers a clear search demand for a versatile, durable, and accessible printing method. Successful content from ranking websites focuses on answering specific long-tail queries such as "how to apply DTF transfers on polyester," "DTF vs screen printing cost," and "washing instructions for DTF printed shirts." These articles and product pages typically incorporate data on print resolution (often cited as up to 1440 dpi by printer manufacturers), production speed, and material compatibility lists based on technical datasheets from adhesive powder and film suppliers. To optimize for Google search, content must address the user's journey from learning about the technology to purchasing supplies. This includes providing comparative data with other methods, step-by-step application tutorials with precise time, temperature, and pressure settings (e.g., 160-165°C for 12-15 seconds with medium pressure, as commonly recommended by transfer paper manufacturers), and highlighting the tangible benefits proven through user case studies: reduced setup time, lower cost for color-rich designs, and the ability to print on a diverse range of textiles that were previously challenging to decorate with such high quality.

Select the most popular foreign trade service products to meet your diverse needs

Learn more about the dynamics and professional knowledge of the foreign trade industry

Direct-to-Film (DTF) transfers offer a fantastic w...

More

When it comes to transferring designs onto objects...

More

When diving into Direct-to-Film (DTF) printing, on...

More

Make your Halloween tees shine with SAILLAGE’s DTF...

More

Third, BOPP film offers great versatility and safe...

More

Select the most popular foreign trade service products to meet your diverse needs

Explore more content related to foreign trade services

Tel: +86 17706217416

Add: Building L2A, No. 520, Lane 1588, Zhuguang Road, Hongqiao World Center, Qingpu District, Shanghai, China

User Comments

Service Experience Sharing from Real Customers

Sarah Johnson

Graphic DesignerThis DTF transfer paper is absolutely fantastic! The colors come out vibrant and the transfer is incredibly durable after washing. It's become my go-to for custom apparel projects.

Michael Chen

Print Shop OwnerExcellent quality DTF paper that consistently delivers sharp details and strong adhesion. Our clients love the soft hand feel and we appreciate the reliable performance in our production workflow.

Emily Rodriguez

Small Business OwnerVery impressed with this DTF transfer paper! The application process was straightforward and the results are professional-looking. The transfers hold up well even after multiple washes.

David Thompson

Textile ArtistAs someone who creates custom textile pieces, I'm thrilled with this DTF paper. It handles complex designs with ease and the color reproduction is exceptional. Highly recommended for serious creators!