The Pros and Cons of DTF film printing: A Comprehensive Guide

In the dynamic world of custom apparel printing, b...

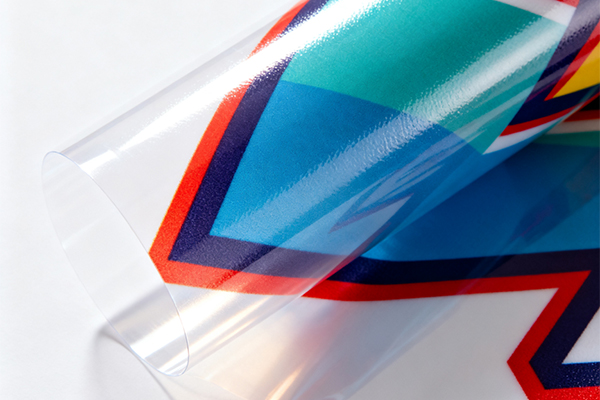

MoreBOPP (Biaxially Oriented Polypropylene) and CPP (Cast Polypropylene) films are both polypropylene-based packaging materials, but they undergo different manufacturing processes and possess distinct characteristics that determine their applications. BOPP films are produced by stretching polypropylene in both machine and transverse directions, enhancing tensile strength, clarity, and barrier properties. In contrast, CPP films are manufactured using a cast extrusion process without orientation, resulting in superior heat sealability and flexibility. These differences impact their performance in areas like moisture resistance, durability, and printability. For instance, BOPP typically has a higher tensile strength (e.g., 150-300 MPa compared to CPP's 50-150 MPa) and better oxygen barrier properties, making it ideal for rigid packaging, while CPP's lower melting point and ease of sealing suit it for flexible packaging like food wraps. Understanding these distinctions helps businesses select the appropriate film based on factors like cost, shelf life, and environmental conditions.

Market data and industry reports highlight practical applications and performance metrics. BOPP films dominate the global packaging market, with a projected CAGR of 6.5% from 2021 to 2028, driven by demand in food packaging (e.g., snacks, confectionery) and labeling due to their high gloss and printability. For example, BOPP films often feature a water vapor transmission rate (WVTR) of 1-2 g/m²/day, ensuring moisture protection for dry goods. In contrast, CPP films are preferred for laminated structures in medical and textile packaging, where heat seal integrity is critical; they can achieve seal strengths of 300-500 N/m. Real-world testing, such as ASTM D882 standards, shows BOPP maintains dimensional stability under stress, while CPP excels in tear resistance (Elmendorf tear strength of 10-20 g for CPP vs. 5-10 g for BOPP). Sustainability trends also influence choice: BOPP is recyclable but requires specialized facilities, whereas CPP's thinner gauges reduce plastic usage by up to 15% in some applications. Brands like Procter & Gamble and Nestlé leverage BOPP for crisp packaging and CPP for flow wraps, optimizing based on product needs. Always consult technical datasheets to verify properties like coefficient of friction (COF) and optical clarity for specific use cases.

Select the most popular foreign trade service products to meet your diverse needs

Learn more about the dynamics and professional knowledge of the foreign trade industry

In the dynamic world of custom apparel printing, b...

More

Third, BOPP film offers great versatility and safe...

More

When it comes to transferring designs onto objects...

More

BOPP Film (Biaxially Oriented Polypropylene Film) ...

More

Flexo printing uses flexible plates to create high...

MoreSelect the most popular foreign trade service products to meet your diverse needs

Explore more content related to foreign trade services

Tel: +86 17706217416

Add: Building L2A, No. 520, Lane 1588, Zhuguang Road, Hongqiao World Center, Qingpu District, Shanghai, China

User Comments

Service Experience Sharing from Real Customers

Michael Chen

Packaging EngineerThis article perfectly clarified the key difference between BOPP and CPP films for our team. BOPP's superior tensile strength makes it ideal for our snack food packaging, while CPP's heat sealability is unmatched. Essential knowledge for material selection!

Sarah Johnson

Procurement ManagerAs someone responsible for sourcing flexible packaging, understanding the distinction between BOPP's stiffness and CPP's clarity has been crucial. This guide helped us optimize our laminate structures, improving product presentation and shelf life.

David Rodriguez

Printing SpecialistThe clear explanation of BOPP vs. CPP film properties transformed our label production. We now use BOPP for its excellent printability and moisture resistance, avoiding the dimensional instability we faced with other materials. A game-changer!

Emily Watson

Product Development ScientistFinally, a resource that details the functional differences! BOPP's high yield strength versus CPP's superior cold-temperature performance directly influenced our pharmaceutical blister packaging design. Highly informative for technical teams.