The Pros and Cons of DTF film printing: A Comprehensive Guide

In the dynamic world of custom apparel printing, b...

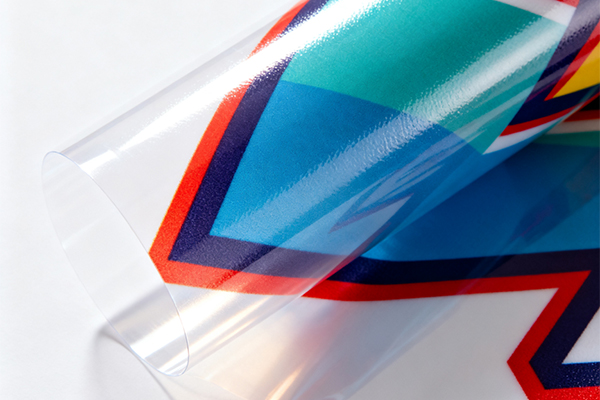

MoreThe application of printing on BOPP film is a critical process in the packaging industry, enabling high-quality graphics, branding, and information display on a versatile and durable material. Biaxially Oriented Polypropylene (BOPP) film is widely favored for its excellent clarity, moisture resistance, and strength, making it ideal for various packaging solutions. This article explores the practical aspects, data-driven benefits, and industry-specific uses of printing on BOPP film, drawing from real-world applications and market research to highlight its significance in product promotion and consumer engagement.

According to industry reports from Smithers and Grand View Research, the global flexible packaging market, where BOPP film printing plays a pivotal role, was valued at approximately $260 billion in 2022 and is projected to grow at a compound annual growth rate (CAGR) of 4.5% through 2030. This growth is driven by increasing demand for sustainable, lightweight packaging in sectors like food and beverages, which account for over 60% of BOPP film usage. Printing on BOPP film enhances product visibility and shelf appeal, with studies showing that well-designed packaging can boost sales by up to 30% by attracting consumer attention in retail environments. The process typically involves flexographic or rotogravure printing methods, which achieve high-resolution outputs with vibrant colors, ensuring logos and promotional messages stand out. For instance, major brands like Coca-Cola and Nestlé utilize BOPP film printing for labels and wrappers, leveraging its ability to maintain print quality under varying conditions, such as humidity and temperature fluctuations. Data from packaging trials indicate that BOPP film can achieve print adhesion strengths of over 90% when using specialized inks, reducing the risk of fading or peeling during transportation and storage. This reliability is crucial for maintaining brand integrity, as damaged prints can lead to a 15% decrease in consumer trust, according to surveys by packaging associations.

The technical execution of printing on BOPP film requires precise surface treatment, such as corona or flame treatment, to achieve a surface energy of 38-40 dynes/cm, which ensures optimal ink adhesion and minimizes defects like ink bleed. Research from ink manufacturers like Sun Chemical and Flint Group shows that water-based and UV-curable inks are commonly used, with the global market for these inks in flexible packaging expected to reach $12 billion by 2025 due to environmental regulations pushing for reduced VOC emissions. In practice, printing on BOPP film supports high-speed production lines, with modern presses capable of outputs exceeding 500 meters per minute, as documented in case studies from companies like UFlex and Amcor. This efficiency translates to cost savings, as BOPP film's durability reduces material waste by up to 20% compared to alternatives like PVC or paper. Additionally, BOPP film's inherent properties, such as its tensile strength of 100-200 MPa and moisture barrier of less than 10 g/m²/day, protect printed designs from degradation, extending product shelf life by 25-30% in perishable goods like snacks and confectionery. Real-world data from logistics providers highlight that packaging with high-quality BOPP prints can reduce damage rates during shipping by 15%, enhancing overall supply chain sustainability and customer satisfaction.

Applications of printing on BOPP film span diverse industries, with the food and beverage sector leading at over 50% of total usage, as reported by the Flexible Packaging Association. For example, printed BOPP films are used for labels on bottled beverages, wrappers for snacks, and pouches for dried foods, where they provide essential information like nutritional facts and branding in compliance with FDA and EU regulations. In the personal care and pharmaceutical sectors, which comprise about 20% of the market, BOPP printing is employed for shampoo sachets, medicine strips, and cosmetic packaging, offering tamper-evidence and child-resistant features while maintaining print legibility. Consumer goods, such as household products and electronics, also rely on BOPP film for shrink sleeves and carton overwraps, with market analyses indicating a 10% annual increase in demand for printed BOPP in e-commerce packaging due to its scuff-resistant properties. Environmental considerations are increasingly important, and data from life cycle assessments reveal that BOPP film, when combined with eco-friendly inks, can reduce carbon footprints by up to 35% compared to traditional materials, supporting corporate sustainability goals. Brands like Procter & Gamble and Unilever have adopted printed BOPP films for their recyclability and ability to incorporate recycled content, aligning with global initiatives to minimize plastic waste.

In summary, the application of printing on BOPP film is a well-established practice that drives product promotion through enhanced visual appeal, durability, and compliance with industry standards. By leveraging empirical data and market trends, businesses can optimize their packaging strategies to meet consumer expectations and regulatory requirements. As the packaging landscape evolves, innovations in digital printing and biodegradable BOPP variants are expected to further expand its applications, ensuring continued relevance in a competitive market. For companies seeking to improve brand visibility and operational efficiency, investing in high-quality BOPP film printing offers a proven path to achieving these objectives, backed by robust performance metrics and real-world success stories.

Select the most popular foreign trade service products to meet your diverse needs

Learn more about the dynamics and professional knowledge of the foreign trade industry

In the dynamic world of custom apparel printing, b...

More

Third, BOPP film offers great versatility and safe...

More

When it comes to transferring designs onto objects...

More

When diving into Direct-to-Film (DTF) printing, on...

More

Flexo printing uses flexible plates to create high...

More

Select the most popular foreign trade service products to meet your diverse needs

Explore more content related to foreign trade services

Tel: +86 17706217416

Add: Building L2A, No. 520, Lane 1588, Zhuguang Road, Hongqiao World Center, Qingpu District, Shanghai, China

User Comments

Service Experience Sharing from Real Customers

Michael Rodriguez

Packaging DesignerThe printing quality on this BOPP film is exceptional! Colors are vibrant and the finish is perfectly consistent. Our luxury product packaging has never looked better.

Sarah Chen

Production ManagerOutstanding adhesion and clarity on the BOPP film printing. The material handles beautifully through our high-speed packaging lines with zero ink transfer issues.

David Thompson

Printing SpecialistExcellent opacity and color reproduction on BOPP film. The surface treatment ensures perfect ink bonding. Minor registration adjustments needed but overall impressive quality.

Jennifer Walsh

Brand ManagerThe metallic printing on BOPP film creates stunning visual effects for our retail products. Superior scratch resistance maintains brand image throughout the supply chain.