Flexo Printing Explained for Self Adhesive Label Films

Flexo printing uses flexible plates to create high...

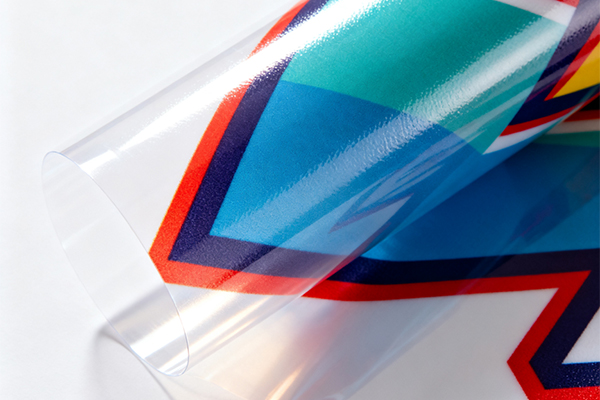

MoreClear self adhesive PP (polypropylene) jumbo rolls are large-format, industrial-grade materials primarily used for manufacturing packaging tapes, labels, and protective films. These rolls consist of a clear, biaxially oriented polypropylene (BOPP) film coated with a high-tack, pressure-sensitive adhesive, typically acrylic or hot melt, and a silicone-coated release liner. The "jumbo" designation refers to their substantial dimensions, often exceeding 1,000 meters in length and 1.5 meters in width, making them a cost-effective raw material for converters and large-scale end-users. The core utility of this product lies in its versatility, clarity, and durability, serving as a foundational component across numerous industries where clear, strong, and adhesive-backed materials are required for sealing, identification, protection, and presentation.

The applications for clear self adhesive PP jumbo rolls are extensive and critical to modern supply chains and retail operations. In the packaging industry, they are the primary raw material slit down to create clear packaging tapes. These tapes are favored for their high tensile strength, excellent clarity that doesn't obscure box printing, and resistance to moisture and abrasion. According to market analyses from sources like Smithers and industry platforms such as Packaging Gateway, the global demand for BOPP tapes has been growing steadily, with a significant portion of this growth attributed to the e-commerce sector's expansion. The strength of PP tape ensures carton integrity during transit, reducing the risk of tampering and product damage. Beyond tapes, these jumbo rolls are fundamental in the label manufacturing sector. They are converted into clear product labels for a vast array of consumer goods, including food and beverage bottles, cosmetic containers, and retail products. The crystal-clear finish provides a "no-label look" that enhances product appeal by allowing the container's color and branding to show through uninterrupted. This application is particularly dominant in industries where aesthetic presentation is directly linked to consumer perception and sales, such as craft beverages and high-end cosmetics. Furthermore, the material's properties make it suitable for producing protective films. These films are applied to sensitive surfaces like acrylic sheets, polycarbonate panels, and stainless-steel appliances to guard against scratches, dust, and scuffs during manufacturing, storage, and installation. The adhesive is designed to be strong enough to hold the film securely but removable without leaving residue, a key requirement in industrial and construction settings. The durability of PP film also allows it to be used in outdoor applications, such as temporary protective layers on solar panels or automotive parts, where it must withstand UV exposure and varying weather conditions for a limited period. The economic advantage of purchasing in jumbo roll format is substantial for converters. By buying in bulk, manufacturers of tapes and labels significantly reduce their per-unit material cost. This economy of scale is crucial in a highly competitive market. Data from converter case studies and industry reports on platforms like Labels & Labeling indicate that optimizing jumbo roll usage can lead to a 15-25% reduction in raw material costs compared to purchasing pre-converted, smaller rolls. This efficiency is achieved by minimizing the frequency of roll changes on slitting and printing machinery, thereby reducing downtime and labor. The technical specifications of these rolls, such as adhesive thickness, liner type, and film gauge, can be customized to meet specific end-use requirements. For instance, a tape manufacturer serving the frozen food logistics industry would require a jumbo roll with an adhesive formulated for low-temperature performance, ensuring it remains effective in cold storage environments. Similarly, a label converter for chemical products would need a PP face stock with high resistance to oils and solvents. This level of customization, combined with the material's inherent moisture resistance, dimensional stability, and excellent printability (compatible with flexographic, digital, and UV inkjet printing), makes clear self-adhesive PP jumbo rolls an indispensable and highly adaptable material for industrial and commercial production.

Select the most popular foreign trade service products to meet your diverse needs

Learn more about the dynamics and professional knowledge of the foreign trade industry

Flexo printing uses flexible plates to create high...

More

BOPP Film (Biaxially Oriented Polypropylene Film) ...

More

For a leading Pearlized BOPP Film manufacturer, qu...

More

Sports are all about unity—and nothing fuels team ...

More

Direct-to-Film (DTF) transfers offer a fantastic w...

MoreSelect the most popular foreign trade service products to meet your diverse needs

Explore more content related to foreign trade services

Tel: +86 17706217416

Add: Building L2A, No. 520, Lane 1588, Zhuguang Road, Hongqiao World Center, Qingpu District, Shanghai, China

User Comments

Service Experience Sharing from Real Customers

Michael Thompson

Packaging ManagerThe clarity and adhesive strength of this PP jumbo roll are exceptional. It has significantly improved our packaging line efficiency with zero residue issues.

Sarah Chen

Printing SpecialistExcellent material consistency and easy unwinding. The self-adhesive property works perfectly with our labeling machines. Minor trimming needed but overall great value.

David Rodriguez

Warehouse SupervisorThis jumbo roll lasts forever in our shipping department. The transparency makes barcode scanning flawless and the adhesive never fails in humid conditions.

Emily Watson

Product DesignerAs a craft supplies retailer, we appreciate how cleanly it cuts and its repositionable feature. Customers love the professional finish it gives to handmade products.