How Pearlized BOPP Film Manufacturer Conducts Quality Inspection for his Film

For a leading Pearlized BOPP Film manufacturer, quality inspection is not just a final step; it is an integral part of the entire production philosophy. It is the unwavering commitment that transforms raw materials into the consistent, high-performance material demanded by premium packaging brands. The rigorous quality inspection process for Pearlized BOPP Film ensures every roll meets exacting standards for aesthetics and performance. This is a behind-the-scenes look at how a professional manufacturer guarantees excellence.

The journey of quality begins long before the film is wound. It starts with raw material qualification. A reputable Pearlized BOPP Film manufacturer will meticulously vet every batch of polypropylene and pearlescent masterbatch. This initial scrutiny is critical, as the purity and quality of these inputs directly influence the clarity, sparkle, and durability of the final Pearlized BOPP Film.

During the extrusion and casting process, inline monitoring systems provide real-time data. Sophisticated sensors continuously measure the thickness profile across the entire web of the Pearlized BOPP Film. This ensures micron-level consistency, which is paramount for preventing issues like wrinkling or tension variations during high-speed printing and laminating. Any deviation is corrected instantly, minimizing waste and ensuring uniformity.

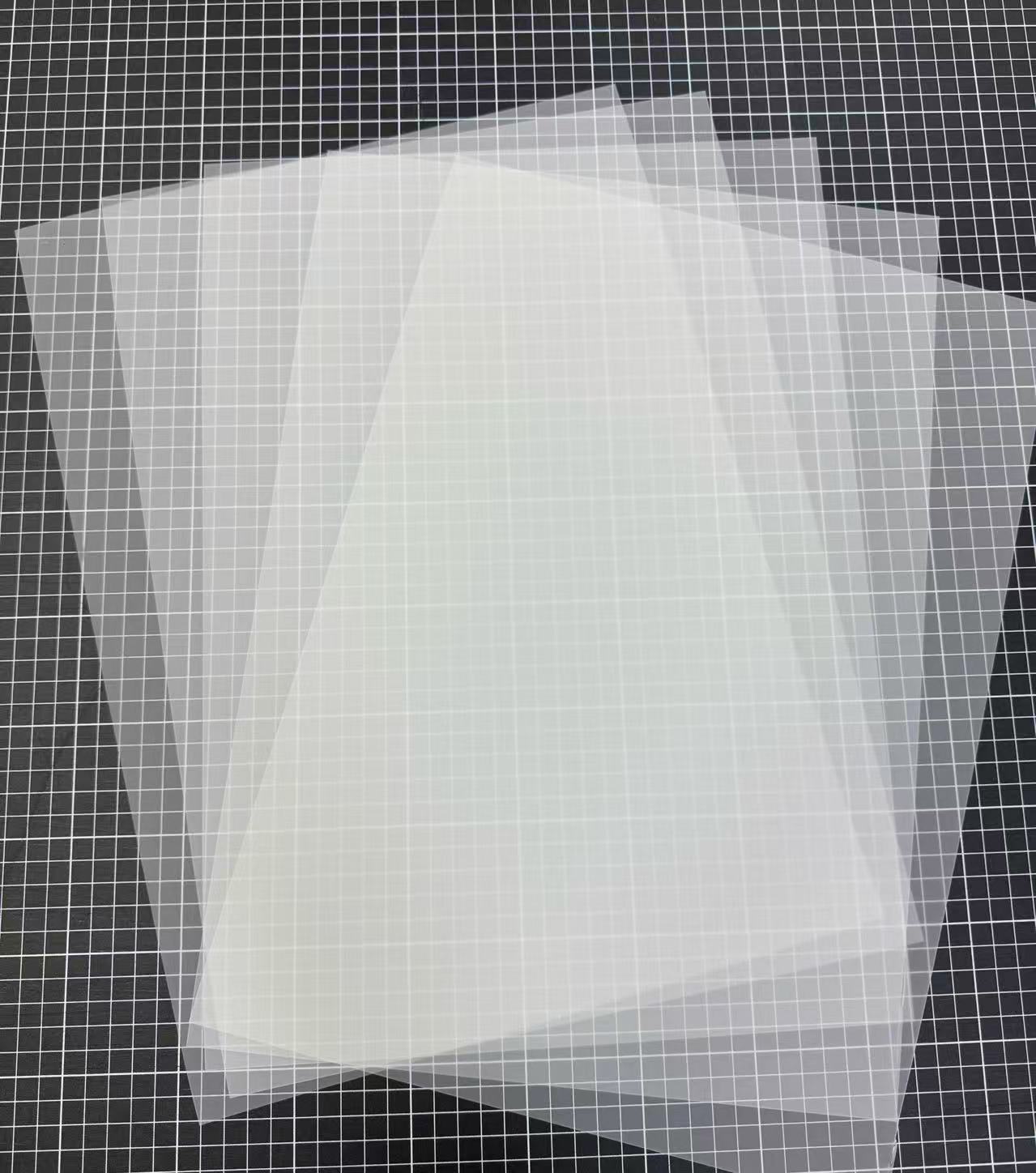

Once the film is produced, it enters the offline quality control lab. Here, technicians conduct a multi-point inspection. The visual appeal of the Pearlized BOPP Film is paramount. Under controlled lighting, experts examine the surface for any imperfections—scratches, gels, or contaminants—that could mar the signature pearlescent sheen. The gloss level is quantitatively measured with a gloss meter to ensure it meets the specified brilliance.

The physical properties of the Pearlized BOPP Film are then rigorously tested. Tensile strength and elongation tests confirm the film can withstand the stresses of converting and end-use. Slip and surface tension are checked to guarantee optimal performance on packaging lines. For barrier applications, tests for moisture and oxygen transmission rates are conducted. This data-driven approach separates a quality-focused Pearlized BOPP Film manufacturer from the competition.

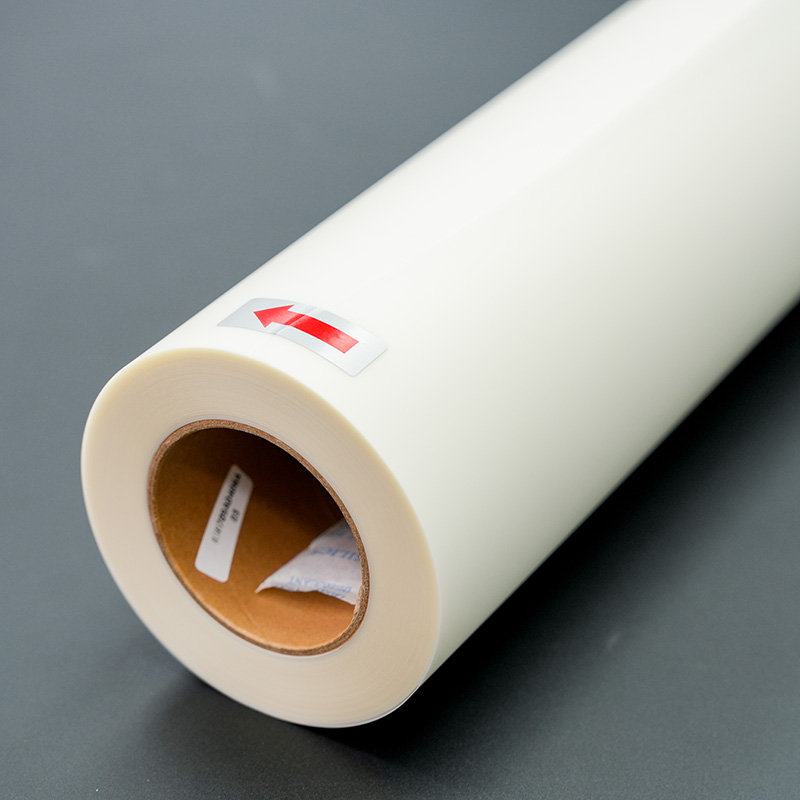

Finally, the roll itself is inspected. The winding must be perfect—tight, even, and free from defects like telescoping. This attention to detail ensures that the customer’s experience with the Pearlized BOPP Film is flawless from the first meter to the last. By embedding quality checks at every stage, a manufacturer doesn’t just inspect quality; they build it directly into the DNA of their Pearlized BOPP Film.

contact us

contact

Tel: +86 17706217416

Add: Building L2A, No. 520, Lane 1588, Zhuguang Road, Hongqiao World Center, Qingpu District, Shanghai, China