How to Classify BOPP Films According to Their Surface Condition

BOPP Film (Biaxially Oriented Polypropylene Film) is widely used in modern packaging, labeling, and lamination thanks to its excellent mechanical strength, high clarity, and moisture-resistant performance. One key way to categorize BOPP Film is by analyzing its surface condition. This classification helps packaging manufacturers, printers, and converters choose the right film grade for their specific application needs. Understanding how to classify BOPP Film according to surface condition ensures better printability, barrier performance, lamination quality, and sealing results.

1. Understanding BOPP Base Film

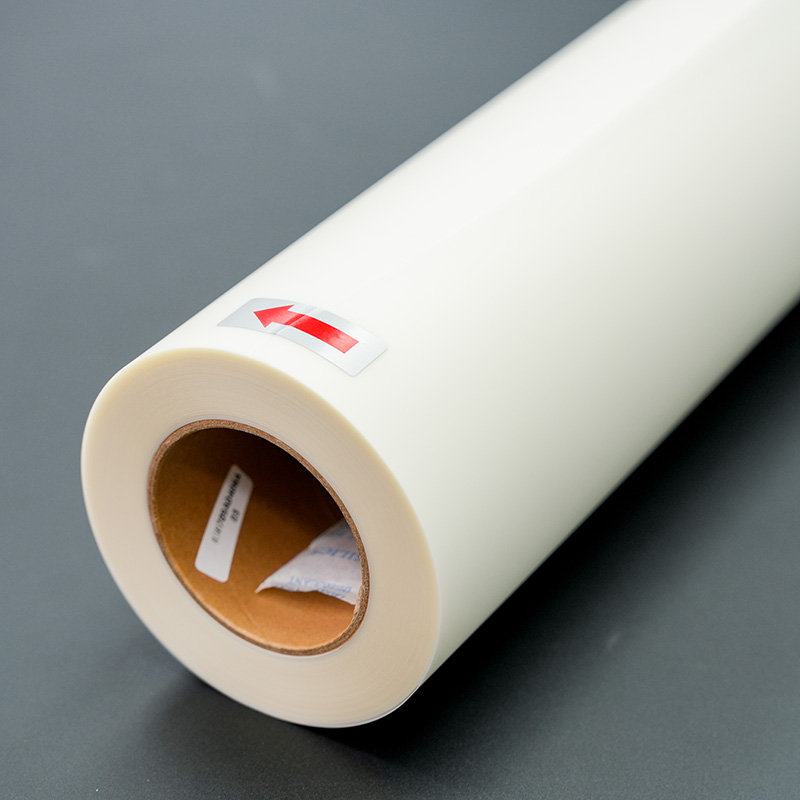

The first category in this classification system is BOPP base film. BOPP base film refers to the original film produced immediately after extrusion and biaxial stretching. At this stage, the film has excellent clarity, strength, and flexibility, which are inherent characteristics of BOPP Film.

However, BOPP base film typically has not undergone any surface treatment or coating. This unmodified surface is suitable for further processing, such as lamination or metallization. Manufacturers often select BOPP base film when they need a primary substrate for value-added applications where coating or printing will be applied later in the production process.

2. What is Uncoated BOPP Film?

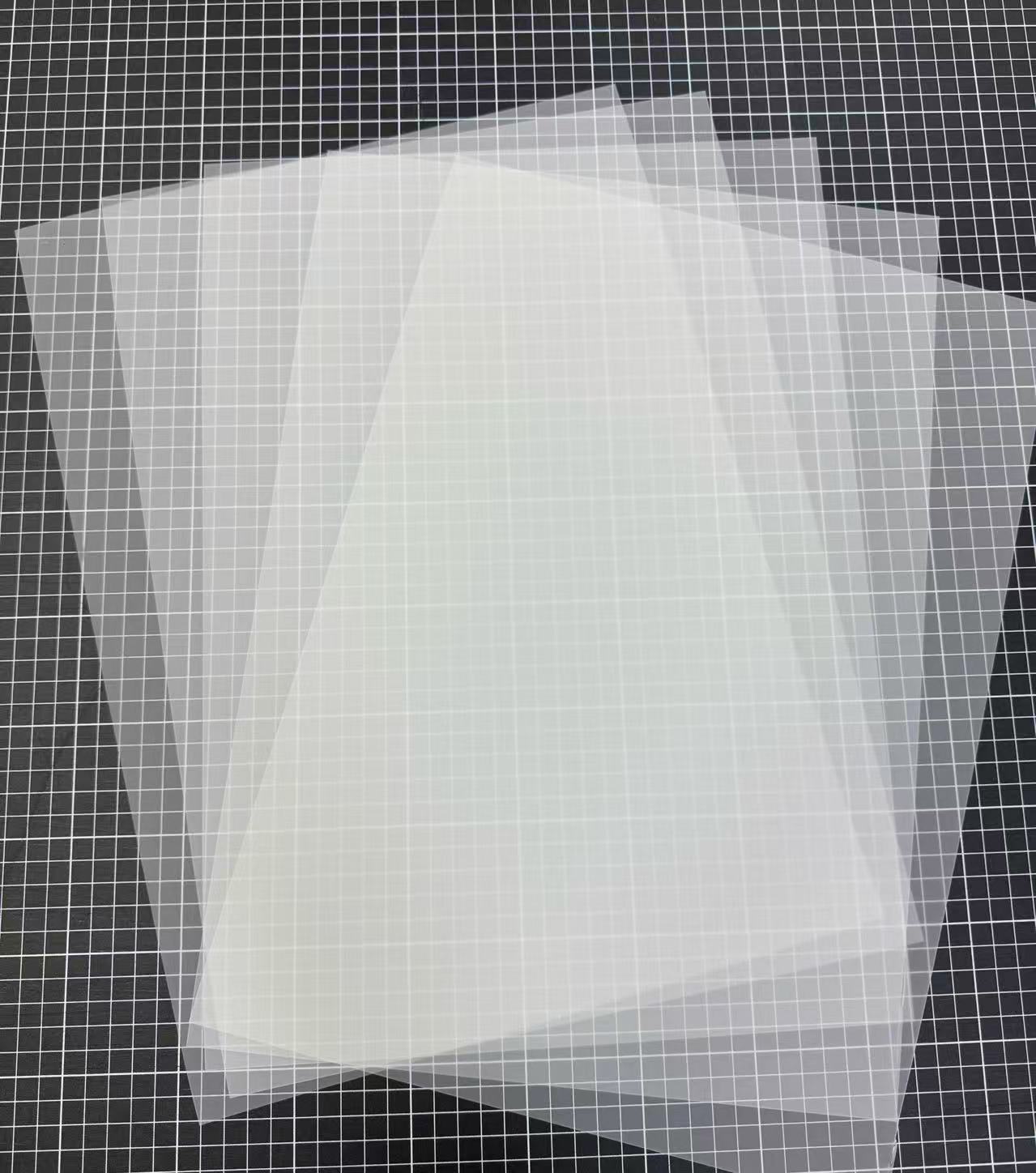

The next important classification is uncoated BOPP film. Uncoated BOPP film has no surface coating layer and primarily receives corona or flame treatment to enhance surface energy. This treatment improves ink adhesion and makes uncoated BOPP film suitable for printing and general packaging needs.

Although simple in structure, uncoated BOPP film provides outstanding clarity, good stiffness, and excellent moisture barrier performance. It is widely used in everyday packaging applications such as snack wrappers, labels, flower sleeves, and general protective packaging. Many manufacturers prefer uncoated BOPP film for cost-efficient production while maintaining good printing results.

3. Coated and Surface-Treated BOPP Film

In addition to BOPP base film and uncoated BOPP film, some BOPP Film grades undergo special surface treatments. These coated films may include acrylic coating, PVDC coating, or heat-seal layers to enhance barrier properties, sealing performance, and printability. These films are chosen for premium food packaging, high-speed printing jobs, and applications requiring extended shelf life.

Conclusion

By understanding BOPP base film, uncoated BOPP film, and coated surface-treated options, businesses can select the right BOPP Film for printing, lamination, and packaging applications. Proper classification ensures optimal performance, cost efficiency, and product appeal across the packaging industry.

News & Events

learn more-

Blog

Press Release Nov-07-2025

Blog

Press Release Nov-07-2025What is BOPP Film

BOPP Film, short for Biaxially Oriented Polypropylene Film, is one of the most widely used packaging materials in the world today. -

Blog

Press Release Nov-07-2025

Blog

Press Release Nov-07-2025What are the Differences Between BOPP Film & BOPET Film

In the packaging industry, two of the most popular materials are BOPP Film (Biaxially Oriented Polypropylene) and BOPET Film (Biaxially Oriented Polyethylene Terephthalate). -

Blog

Press Release Nov-07-2025

Blog

Press Release Nov-07-2025What are the advantages of BOPP film

Third, BOPP film offers great versatility and safety. It’s FDA-approved for direct food contact, making it ideal for snack packs, cereal liners, and fresh produce bags.

contact us

contact

Tel: +86 17706217416

Add: Building L2A, No. 520, Lane 1588, Zhuguang Road, Hongqiao World Center, Qingpu District, Shanghai, China