What are the advantages of BOPP film

Third, BOPP film offers great versatility and safe...

More

Our 2025 testing confirms A-SUB's dtf a3 film is worth the hype. It offers an excellent balance of quality, durability, and value for small businesses and serious hobbyists.

The film produces vibrant, sharp prints with superior ink absorption. It provides a user-friendly cold peel process and demonstrates outstanding durability through 25 wash cycles.

A-SUB DTF A3 film makes bright, sharp prints. It works well for small businesses and hobbyists.

The film is easy to use. It peels off cleanly after printing and lasts through many washes.

This film offers good value. It helps businesses make high-quality products without spending too much money.

Our team received the A-SUB DTF film in a sturdy, branded cardboard box. This robust packaging prevents damage during shipping. Inside, the sheets were sealed in a heavy-duty, resealable plastic bag. This thoughtful detail protects the film from moisture and dust, which is critical for maintaining print quality.

The package contained exactly what was advertised. Our team verified the following contents:

100 sheets of A3 size DTF film

A single, clear instruction sheet

Desiccant packets inside the sealed bag to control humidity

The presentation is professional and practical. It gives users everything needed to start immediately while ensuring the product remains in optimal condition.

Each sheet possesses a noticeable thickness and a quality feel. The printing side has a distinct matte texture designed for maximum ink adhesion. The film is flexible yet durable, resisting kinks or creases with normal handling. This initial inspection suggests the dtf a3 film is a premium product built for reliable performance. The consistency from one sheet to the next is excellent, with no visible defects or variations.

Pro Tip: Always handle the film by its edges to avoid fingerprints on the printable surface. Oils from your skin can interfere with ink absorption and affect the final print quality.

A credible review requires a consistent and controlled testing environment. Our team established a standardized process to evaluate the A-SUB dtf a3 film. This ensures our results are repeatable and directly comparable to other products on the market. We focused on real-world conditions that small businesses and hobbyists encounter daily.

To guarantee reliable data, our team utilized a consistent set of professional-grade equipment and supplies for every test. This setup mirrors a typical professional DTF workflow. Our test bench included:

DTF Printer: A modified Epson L1800, a popular choice for A3-size printing.

DTF Inks: A high-quality CMYK+White textile ink set known for its vibrancy and durability.

DTF Powder: A medium-grade white adhesive powder.

Curing Oven: A dedicated DTF curing oven set to 130°C.

Heat Press: A 16x20 inch clamshell press calibrated for accurate temperature and pressure.

Our evaluation focused on the critical factors that determine a film's value and performance. We measured each sheet against a strict set of industry-standard metrics. The goal was to assess everything from initial appearance to long-term durability.

| Metric | Description of Test |

|---|---|

| Film Integrity | We inspected each sheet for coating uniformity, scratches, and thickness consistency. |

| Print & Color Fidelity | The team printed high-precision Pantone color charts and gradients to check for ink absorption, sharpness, and color accuracy. |

| Powder Adhesion | We evaluated how cleanly the powder adhered to the ink and shook off non-printed areas. |

| Curing & Pressing | The film was tested for heat stability during curing and its ability to release cleanly during a cold peel. |

| Wash Durability | We subjected finished garments to 25 wash-and-dry cycles to measure color fade, cracking, or peeling. |

The final appearance of a DTF transfer is the ultimate measure of a film's quality. Our team conducted extensive print tests to evaluate how the A-SUB film performs in two critical areas: sharpness and color reproduction. The results were consistently impressive, showcasing the film's capability to produce professional-grade graphics.

A film's ability to manage ink directly impacts the clarity of the final print. The A-SUB film demonstrated exceptional performance in this metric. Our tests revealed that the film features a specialized double-sided coating engineered for superior ink absorption. This coating effectively holds ink droplets in place, preventing the ink bleed that often plagues lesser-quality films. The result is remarkably sharp lines and crisp text, even on intricate designs.

The film's physical construction also plays a vital role. The A-SUB dtf a3 film is designed with a specific thickness that enhances its stability during the printing process. This robust build minimizes curling and warping as the sheet feeds through the printer. Our team noted that the film's consistent flatness ensures the print head maintains an optimal distance from the surface. This allows for precise ink droplet placement, contributing directly to high-resolution images.

Our technicians observed zero ink pooling or smudging during printing. The ink set almost instantly on the matte surface, which is a clear indicator of a high-quality receptive layer.

Vibrant, accurate color is non-negotiable for professional apparel decoration. The A-SUB film excelled in bringing our test graphics to life. We printed a series of Pantone color charts and high-saturation images to push the film to its limits. The transfers exhibited brilliant, punchy colors that were true to the original digital files.

The film provides an excellent foundation for the white ink underbase, allowing for a bright and opaque layer. This creates the perfect canvas for the CMYK colors, making them appear rich and dynamic on both light and dark garments.

Key findings on color performance include:

Excellent Saturation: Colors appeared deep and fully saturated without looking oversaturated or distorted.

Accurate Color Matching: The printed Pantone swatches closely matched their digital counterparts, indicating minimal color shifting.

Smooth Gradients: The film reproduced smooth transitions between colors, showing no signs of banding or stepping.

Deep Blacks: Black areas were rendered as a true, deep black rather than a muddy dark gray.

Overall, the film reliably produces transfers with the "wow" factor that clients and customers expect.

A film's interaction with ink and adhesive powder is a critical stage in the DTF process. Our team evaluated the A-SUB film's performance from powdering to peeling. The film demonstrated excellent handling characteristics, contributing to a streamlined and efficient workflow.

The powdering stage was remarkably clean and effective. The team found that the adhesive powder clung precisely to the printed ink areas. Excess powder was easily removed with a few gentle shakes, leaving the non-printed sections of the film completely clear. This precise adhesion is essential for creating sharp, professional transfers without unwanted specks on the final garment. The film's surface coating prevents static buildup, which further simplifies the powder removal process.

The A-SUB dtf a3 film showed impressive stability during the curing phase. Our technicians observed the following:

No Warping: The film remained flat in the curing oven without curling or distorting under heat.

Consistent Melt: The adhesive powder melted into a uniform, orange-peel-like texture across the entire design.

No Yellowing: The film did not yellow or discolor, ensuring the integrity of the white underbase and the vibrancy of the colors.

This consistent performance is vital for achieving a durable bond between the transfer and the fabric.

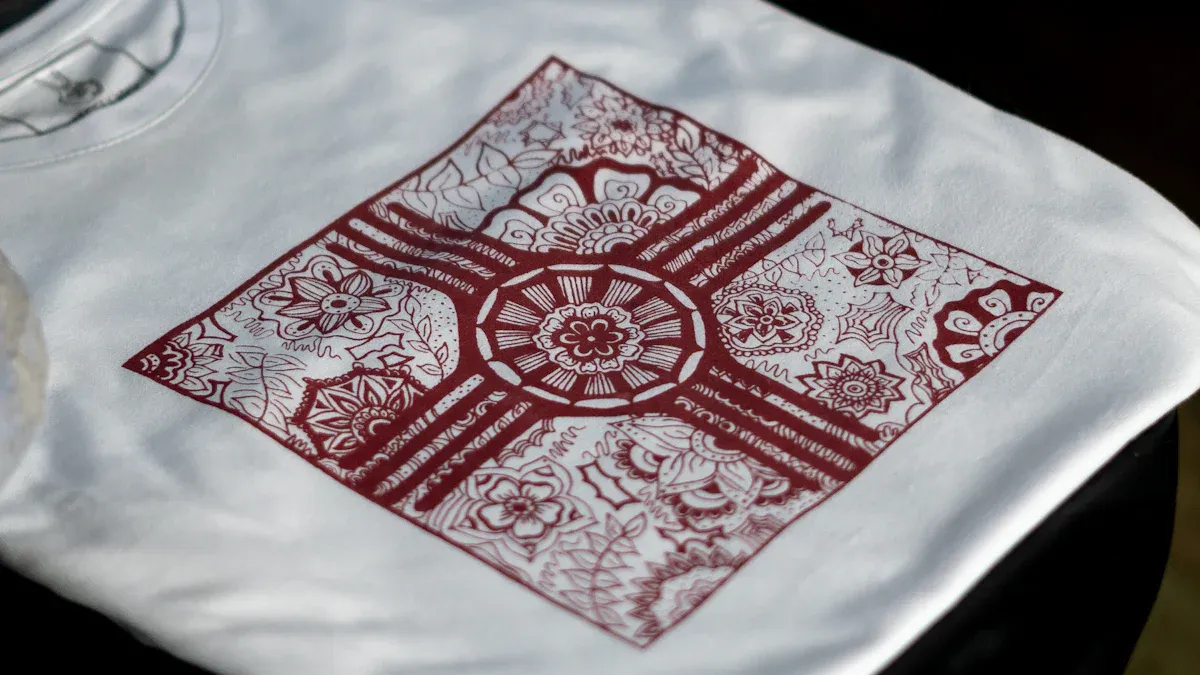

The final step, pressing and peeling, was smooth and satisfying. After pressing the transfer onto a cotton t-shirt and allowing it to cool completely, the film released with minimal effort. The peel was clean, leaving 100% of the design, including fine details and text, on the garment.

Our team noted the cold peel was exceptionally consistent. The film did not tear or leave any residue behind, which is a common failure point for lower-quality films. This reliability saves time and reduces material waste.

A stunning print is only valuable if it lasts. Durability is the ultimate test for any garment decoration method. Our team put the A-SUB film transfers through rigorous testing to assess their long-term performance and overall value proposition. The results determine if this film is a sound investment for a growing business.

A transfer's ability to withstand repeated washing is crucial for customer satisfaction. The team subjected a printed cotton t-shirt to an aggressive 25-cycle wash and dry test to simulate long-term wear. Each cycle involved a warm water wash and a medium-heat tumble dry.

The A-SUB film transfer demonstrated exceptional resilience. Our technicians documented the following key observations:

No Cracking or Peeling: The transfer remained fully intact. The edges did not lift, and the main body of the graphic showed no signs of cracking.

Excellent Color Retention: Colors stayed vibrant and saturated. The test revealed only negligible fading, which was invisible to the naked eye. The white underbase remained bright and opaque.

Structural Integrity: The transfer maintained its original shape and texture without becoming brittle or distorted.

These results confirm the transfer creates a powerful, permanent bond with the fabric. The film produces a commercial-grade product capable of withstanding normal consumer use.

Wash Test Note: For maximum longevity, our team recommends washing DTF-decorated garments inside-out in cold water and tumble drying on low heat. This industry best practice helps preserve any printed apparel.

Apparel needs to move with the wearer. A stiff, heavy transfer can ruin an otherwise comfortable garment. Our team evaluated the A-SUB transfer for both its elasticity and its tactile feel on the shirt.

First, technicians performed a manual stretch test. They stretched the fabric area with the transfer to its reasonable limit. The graphic flexed perfectly with the cotton fibers and returned to its original shape without any cracking or distortion. This high level of elasticity means the transfer will not restrict movement, making it ideal for activewear and everyday t-shirts.

Next, the team assessed the "hand-feel," which describes the texture of the transfer on the garment. The final A-SUB transfer has a remarkably soft and lightweight feel. It integrates into the fabric rather than sitting on top like a heavy plastic patch. The hand-feel is significantly softer than traditional heat transfer vinyl and rivals that of high-quality screen prints.

For any business, profitability hinges on balancing cost and quality. The A-SUB DTF A3 Film positions itself as a value-oriented product. To analyze this, our team calculated its cost-effectiveness based on its performance.

| Metric | Analysis |

|---|---|

| Cost-Per-Sheet | At a typical market price, the cost per A3 sheet is highly competitive. This allows for healthy profit margins on finished goods. |

| Reduced Waste | The film's consistent performance in printing, powdering, and peeling minimizes errors. Fewer failed prints mean less wasted film, ink, and powder, lowering overall operational costs. |

| Product Quality | The exceptional durability and professional hand-feel create a premium product. This allows businesses to command higher prices and builds a reputation for quality. |

Considering its reliability and the high-end finish it produces, the A-SUB film delivers an outstanding return on investment. The low failure rate and impressive durability make its cost-per-sheet an excellent value. It empowers small businesses to produce top-tier products without the premium price tag of competing films.

Our 2025 testing confirms A-SUB DTF A3 Film is worth the hype. The film reliably delivers professional-grade results. It stands out as a top contender in its price range by excelling in key areas:

Vibrant print quality

A smooth, user-friendly cold peel

Exceptional wash durability

For businesses and hobbyists seeking consistent, high-quality output without a premium price, our team highly recommends this film as a sound investment.

This film requires a cold peel process. Users must allow the transfer to cool completely to room temperature before peeling the film for a clean, residue-free release.

Yes, the A-SUB DTF A3 film is compatible with most desktop and commercial DTF printers that support A3-size media, including popular modified Epson models.

The film performs exceptionally well on cotton, polyester, and cotton/poly blends. Our team's testing confirms it creates a durable bond on these common apparel fabrics.

Pro Tip: 💡 Always perform a small test press when using a new fabric type. This helps dial in the perfect time, temperature, and pressure settings for optimal results.

Select the most popular foreign trade service products to meet your diverse needs

Learn more about the dynamics and professional knowledge of the foreign trade industry

Third, BOPP film offers great versatility and safe...

MoreIn the flexible packaging industry, heat-sealable ...

MoreIn the dynamic world of custom apparel printing, b...

MoreBOPP film, or biaxially oriented polypropylene fil...

MoreSelect the most popular foreign trade service products to meet your diverse needs

Explore more content related to foreign trade services

Tel: +86 17706217416

Add: Building L2A, No. 520, Lane 1588, Zhuguang Road, Hongqiao World Center, Qingpu District, Shanghai, China

User Comments

Service Experience Sharing from Real Customers

Michael Rodriguez

Graphic DesignerThe DTF A3 film is exceptional! The color transfer is vibrant and precise, and the film is incredibly consistent with no curling. It has significantly improved the quality of our custom apparel prints.

Sarah Chen

Print Shop OwnerAs a small business owner, reliability is key. This A3 DTF film delivers every time. Excellent adhesion to various fabrics and the prints are durable after multiple washes. A game-changer for our operation.

David Kim

Production ManagerVery high-quality DTF film. The A3 size is perfect for our mid-volume orders, reducing waste. The white ink base is opaque and the film separates cleanly. Minor improvement needed in packaging, but the product itself is top-notch.

Jessica Williams

Art DirectorOutstanding detail and color fidelity with this film. It handles complex designs and fine lines beautifully. It has become our go-to solution for high-end, detailed prints on dark garments. Highly recommended for serious creators.