Brand Story

Company Overview

Officially registered in Shanghai, China—a core hub of economic innovation and industrial development—our company has solidified its market position over two decades by mastering sophisticated manufacturing processes and cutting-edge coating technologies. This long-standing expertise has enabled us to build a highly integrated and relatively complete product industrial chain, eliminating reliance on external suppliers for key components. Our self-produced product portfolio encompasses high-quality base film materials such as BOPP Films, PETG Heat Shrink Film, high-performance adhesives, and custom-formulated coating fluids, Additionally, we bring out cutting-edged Direct-To-Film (DTF) that has excellent compatibility between equipment and core consumables in textile heat transfer industry. We also provide Self Adhesive Films that applied in various application such as label-making industry and soft packaging industry, etc. Each undergoing strict quality control to ensure consistency and reliability, laying a solid foundation for delivering end-to-end solutions to our clients.

Manufacturing Bases

Strategically located across China, our two manufacturing bases cover a combined area of 400,000 square meters—a scale that reflects our strong production capacity and ambition for expansion. These bases are equipped with world-class infrastructure, including advanced warehousing systems, efficient logistics networks, and environmentally friendly facilities, enabling streamlined production processes from raw material intake to finished product delivery. The rational layout of the two bases also allows us to optimize resource allocation, reduce transportation costs, and quickly respond to the diverse needs of customers in different regions across the country.

North China Production Base

East China Production Base

Team Strength

Mature Product System

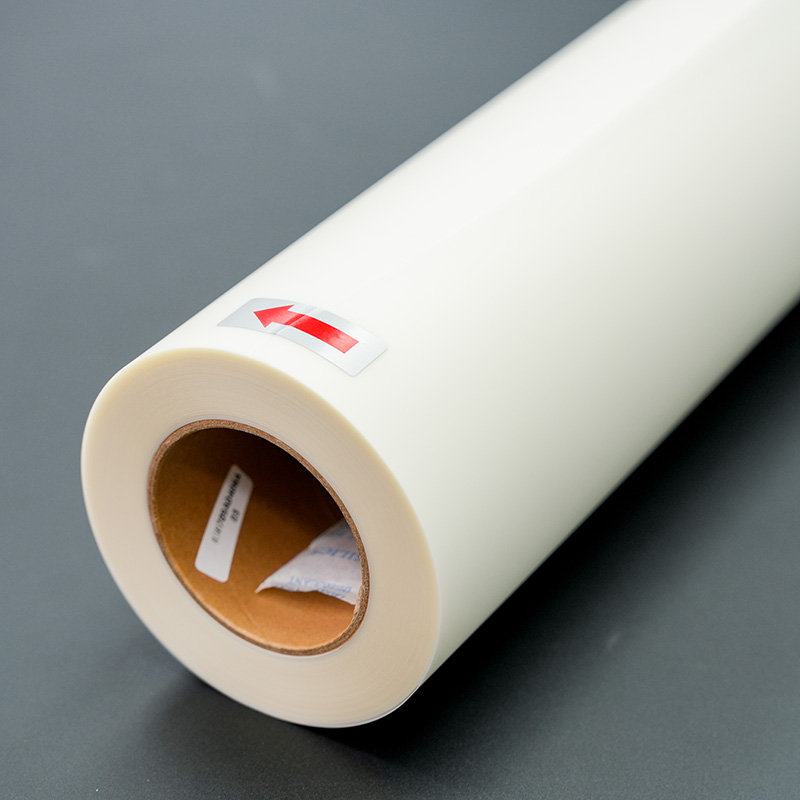

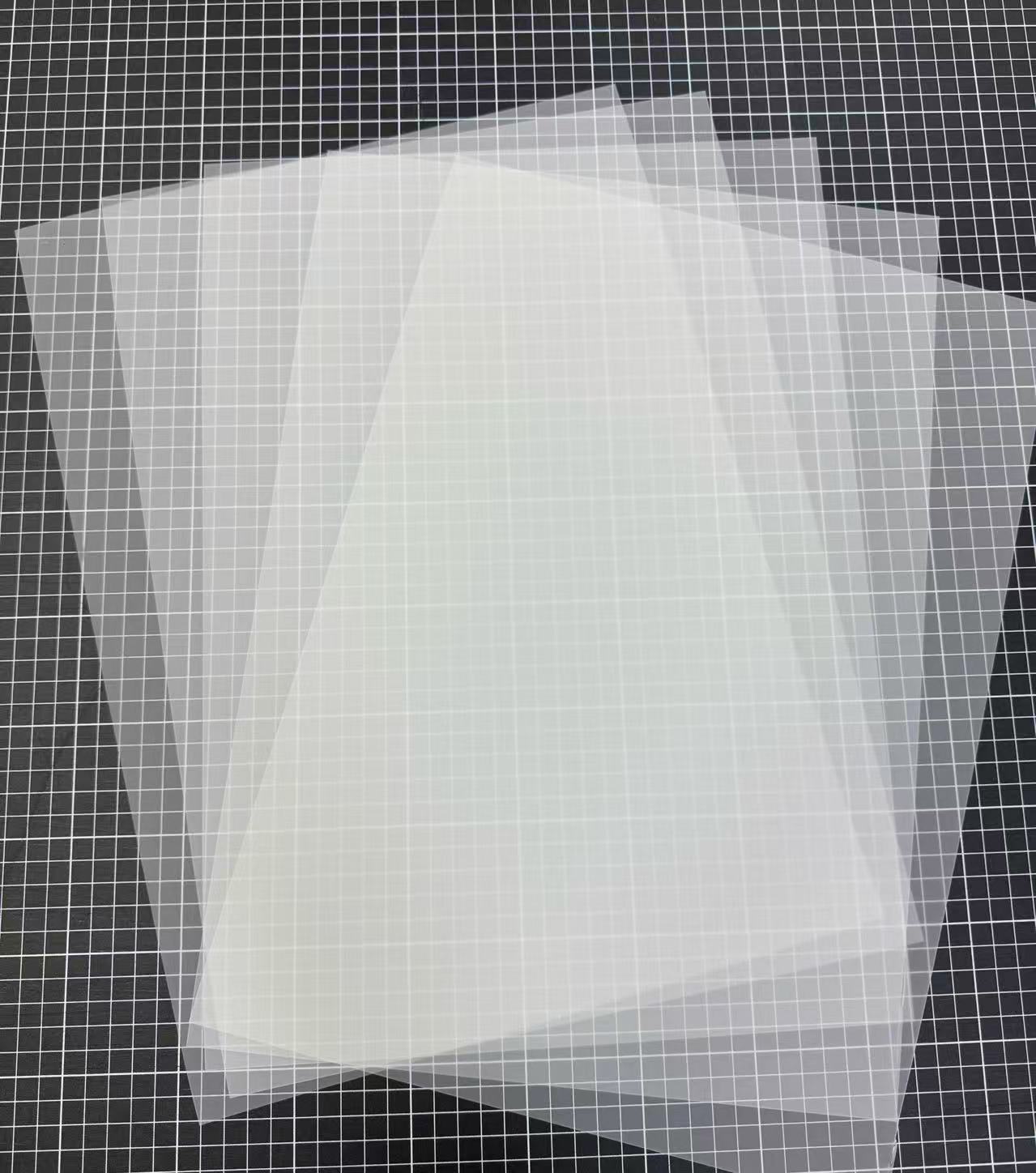

Our product system is meticulously developed to cover the entire value chain of the printing and packaging industry, from upstream to downstream. On the upstream side, we produce high-performance base films that serve as the critical foundation for various printing and packaging applications, offering excellent durability, flexibility, and compatibility with different processing techniques. Moving downstream, we provide a comprehensive range of end-terminal products, including advanced coated printing materials that deliver superior print quality and adhesion, as well as high-efficiency thermal transfer materials suitable for a wide array of industries such as textiles and food packaging. This full-spectrum product offering allows us to cater to the diverse needs of customers, from small-scale enterprises to large multinational corporations, and build long-term partnerships based on trust and mutual benefit.

Advanced Production Lines

Coating Lines

Over 60 high-precision fully automatic coating lines, equipped with advanced control systems that enable real-time monitoring and adjustment of coating thickness, speed, and temperature. This ensures consistent product quality, with an annual coating capacity of 1.8 billion square meters—sufficient to meet the growing demands of both domestic and international markets.

Two fully imported BOPP (Biaxially Oriented Polypropylene) production lines, featuring the widest width in the industry (up to 8.7 meters). These lines adopt advanced extrusion and stretching technologies, producing high-performance BOPP films with excellent transparency, tensile strength, and barrier properties, with an annual output of 50,000 tons.

PETG Production Lines

DTF Coating Lines

Eight fully intelligent DTF (Direct to Film) coating lines, integrated with automated feeding, coating, drying, and winding systems. These lines significantly improve production efficiency while reducing labor costs, with an annual coating output of 100 million square meters, meeting the rising demand for custom DTF printing solutions in the textile and advertising industries.

Strong R&D Capabilities

Innovation is the driving force behind our company’s growth, and we invest heavily in research and development to stay at the forefront of industry technology:

Talent Team

Our R&D team consists of 60 highly qualified professionals, all holding a master’s degree or above, with extensive experience in materials science, chemical engineering, and process optimization. Many of our R&D members have worked in leading international companies or research institutions, bringing advanced technical knowledge and innovative thinking to our projects.

Financial Investment

We have consistently increased our R&D investment over the years, with a cumulative investment of 13 million US dollars. This funding is allocated to support new product development, process improvement, and technology innovation, ensuring that we can quickly translate cutting-edge ideas into marketable products.

Equipment & Facilities

Laboratory Space

Covering an area of over 5,000 square meters, our laboratory is divided into specialized zones for material research, process development, and product testing. The spacious and well-equipped laboratory provides an ideal environment for our R&D team to carry out collaborative research and accelerate the pace of innovation.

Development Philosophy

Guided by the philosophy of “pursuing sustainable development through balanced growth,” we are deeply committed to promoting the circular economy and caring for the well-being of our employees. In terms of environmental responsibility, we integrate eco-friendly practices into every stage of our production process, from selecting recycled raw materials to implementing energy-saving technologies and waste reduction measures, aiming to minimize our carbon footprint and contribute to a greener planet. For our employees, we prioritize their physical and mental health, providing safe working conditions and childcare facilities, and opportunities for personal and professional development. We believe that only by balancing economic benefits with environmental protection and employee care can we achieve long-term, stable development and make meaningful contributions to the improvement of the environment and the sustainable development of society as a whole.

Certifications

To ensure that our film products and management systems meet international standards, we have obtained a series of prestigious certifications, including ISO (International Organization for Standardization) certifications covering quality management, environmental management, and occupational health and safety management. Additionally, we hold FSC (Forest Stewardship Council) certification, demonstrating our commitment to responsible sourcing of wood-based materials; OEKO-TEX certification, confirming that our products are free from harmful substances and safe for human use; and GRS (Global Recycled Standard) certification, validating our efforts in promoting the use of recycled materials and reducing environmental impact. These certifications not only enhance our credibility in the global market but also reflect our dedication to delivering high-quality, sustainable products to our customers.

contact us

contact

Tel: +86 17706217416

Add: Building L2A, No. 520, Lane 1588, Zhuguang Road, Hongqiao World Center, Qingpu District, Shanghai, China