DTF FILM Holiday Sales Strategy 101: Can You Turn 1 Customer Into 5?

The holiday season brings a flood of new customers...

More

Selecting the correct pet film for dtf printing defines the final product's outcome. Hot peel film delivers maximum speed and a glossy, vibrant finish on simpler graphics. Conversely, cold peel film ensures precision for high-detail designs, providing a premium matte finish and consistent quality for intricate work.

Hot peel film is fast. It gives a shiny look. Use it for simple designs and many items.

Cold peel film is strong. It gives a matte look. Use it for detailed designs and long-lasting items.

Choose your film based on your project. Think about speed, design details, and how long you want it to last.

Choosing the right film requires understanding its core properties. The chemical makeup of the release layer is a primary differentiator. Hot peel films typically use a wax-based layer, while cold peel films use a more stable silicon-based layer. This fundamental difference dictates the peeling process, final appearance, and ideal application for each film type.

Hot peel film prioritizes production speed. Its release layer is engineered for immediate peeling right after heat pressing. This efficiency makes it ideal for high-volume jobs with simpler graphics. The transfer process results in a glossy, shiny finish that makes colors appear exceptionally vibrant and sharp. Businesses focusing on bold, colorful designs for quick turnaround will find hot peel film to be an effective solution.

Cold peel film excels in precision and longevity. The film must cool completely before peeling, a process that stabilizes the transfer. This stability is crucial for reproducing designs with fine lines, small text, and intricate details. The resulting transfers have a modern matte finish and demonstrate remarkable durability.

Did You Know?High-quality cold peel transfers can endure over 50 wash cycles with minimal to no fading or cracking, showcasing superior wash fastness. This makes it the premier pet film for dtf printing when longevity is critical.

Hybrid films offer a versatile alternative, combining the benefits of both hot and cold peel methods. Often marketed as "warm peel," this pet film for dtf printing allows users to peel almost immediately or wait a few seconds. This flexibility provides the efficiency of a hot peel with the increased stability and adhesion of a cold peel, making it suitable for a wide range of designs and fabrics.

A direct comparison between hot peel and cold peel films reveals distinct advantages for specific production goals. The choice impacts everything from workflow efficiency to the final product's aesthetic and durability. Understanding these differences helps businesses align their materials with their operational needs and customer expectations.

The most significant difference lies in the peeling process and its effect on production speed.

Hot Peel: This film allows for immediate peeling after the heat press cycle. The operator can remove the film while it is still hot, creating a continuous, fluid workflow. This process eliminates cooling time and prevents production bottlenecks. For high-volume environments, the efficiency gains are substantial. For example, industry leader DTF Miami Prints reported a 30% reduction in press time after switching to hot peel film, enabling them to increase overall output.

Cold Peel: This film requires the transfer to cool completely to room temperature before peeling. This waiting period stabilizes the adhesive, but it also introduces a pause into the production line.

The table below illustrates the dramatic impact on a batch of 100 shirts.

| Workflow Type | Cooling Time per Shirt | Total Waiting Time (100 shirts) | Production Flow |

|---|---|---|---|

| Cold Peel | 1-2 minutes | 100-200 minutes (1.5-3+ hours) | Halts after each press |

| Hot Peel | 0 minutes | 0 minutes | Continuous, fluid motion |

The peeling method directly influences the final appearance and texture of the graphic on the garment. Cold peel transfers offer a premium, modern finish, while hot peel transfers provide a vibrant, eye-catching look.

| Feature | Hot Peel Transfer | Cold Peel Transfer |

|---|---|---|

| Texture/Finish | Produces a slightly glossier or shinier surface. The sheen makes colors appear bold and vibrant. | Creates a more matte or muted finish. This texture resembles a traditional screen print and feels more integrated into the fabric. |

| Hand-feel | Can feel softer initially due to a thinner adhesive layer. The difference often evens out after the first wash. | Might feel slightly thicker at first. This texture also softens considerably after washing. |

Each film type excels in different applications, making the choice dependent on the design complexity and fabric type.

Hot Peel film is ideal for:

High-Volume Production: Its speed makes it perfect for large orders of event merchandise, promotional apparel, and team uniforms.

Simple, Bold Graphics: Designs with large color blocks and minimal fine detail transfer cleanly and appear exceptionally vibrant.

Polyester & Blends: It performs well on these synthetic fabrics, which often require lower application temperatures.

Cold Peel film is the superior choice for:

High-Detail Graphics: It is essential for successfully transferring designs with fine lines, small text, and intricate patterns.

Specialty Fabrics: It provides excellent adhesion on challenging materials like nylon, leather, canvas, and denim.

Premium Apparel: The resulting matte finish and high durability are perfect for high-end retail products where quality is paramount.

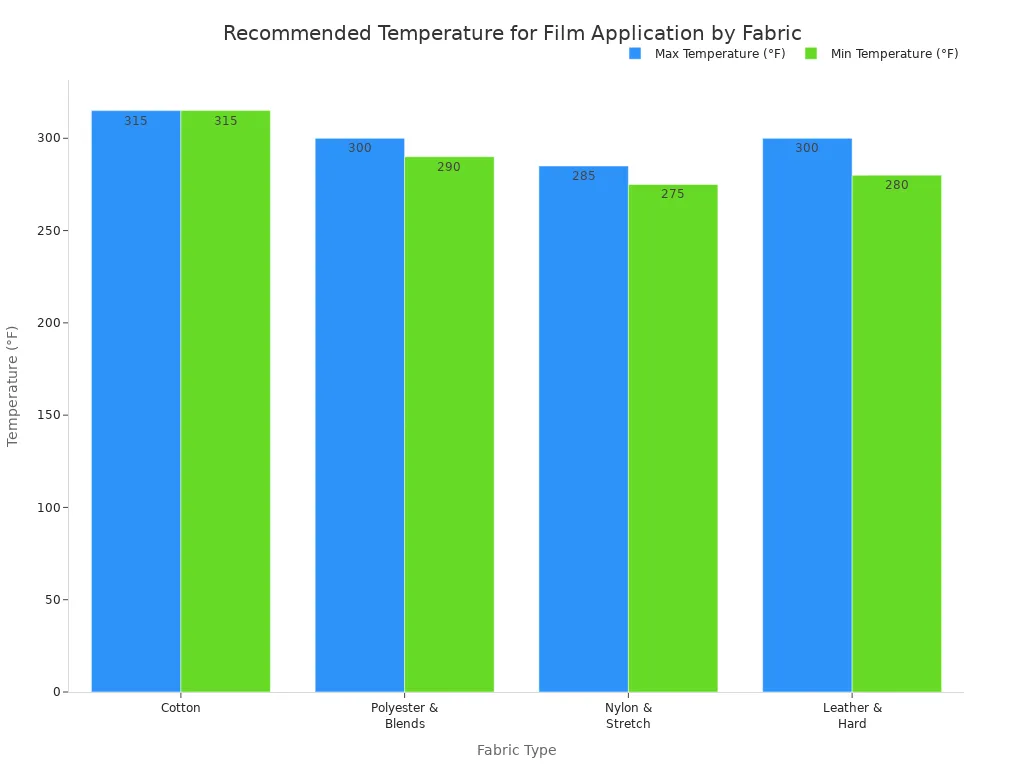

The right pet film for dtf printing often depends on the fabric. The following chart and table provide general temperature and fabric guidelines.

| Peel Type/Fabric | Temperature (°F/°C) | Pressure | Recommended Peel Type |

|---|---|---|---|

| Cotton | 315°F (157°C) | Medium to firm | Cold peel |

| Polyester & Blends | 290-300°F (143-150°C) | Light to medium | Hot peel |

| Nylon & Stretch | 275-285°F (135-140°C) | Light | Cold peel |

| Leather & Hard | 280-300°F (138-150°C) | Medium | Cold peel |

For those new to DTF printing, the learning curve for each film type varies.

Note: Cold peel film is generally more forgiving for beginners. The cooling process allows the adhesive to fully set, reducing the risk of a partial or failed transfer. This stability gives new users more time to get the process right without rushing.

Hot peel film, while faster, requires more precision. Beginners often make mistakes that lead to poor results. Common issues include:

Incorrect Settings: Using the wrong temperature, pressure, or time can cause poor adhesion or scorch marks. The adhesive will not activate properly without sufficient heat.

Insufficient Pressure: Light or uneven pressure prevents the transfer from making full contact with the fabric, leading to patchy results.

Improper Peeling Technique: Peeling too slowly, too early, or at the wrong angle can cause the design to lift or distort.

Moisture in Garment: Forgetting to pre-press the garment leaves moisture and wrinkles, which interfere with adhesion.

Mastering the hot peel process requires practice, but it unlocks maximum production efficiency once perfected.

Businesses select hot peel film for high-volume production and a glossy appearance. They opt for cold peel film when precision and a modern matte finish are most important. Operators should test each pet film for dtf printing to confirm optimal performance with their specific equipment and inks.

Evaluate ink absorption and compatibility to prevent bleeding.

Conduct high-precision print tests to verify accurate color reproduction.

Operators should not use hot peel film for a cold peel. The wax-based release layer is designed for immediate peeling. Waiting for it to cool can cause poor, inconsistent transfers.

Yes, film type impacts durability. Cold peel transfers typically offer superior wash fastness. Their stable adhesion process helps the design withstand dozens of wash cycles with minimal cracking or fading.

Hot peel film generally performs better on polyester and synthetic blends. It adheres well at lower temperatures. This helps prevent scorching or damaging the heat-sensitive fabric during the pressing process.

Leading Precoat Solutions for Advanced Filtration Systems: 2025 Outlook

Innovative Folder Gluer Advancements Shaping 2025 Carton Production Lines

Optimizing Pharma Efficiency: Modern Capsule Decapsulation Machine Innovations Explained

Essential Tablet Sampling Machines: A Comprehensive Laboratory Selection Handbook

Capsule Sorters Demystified: Crucial for Effective Defect Elimination Processes

Select the most popular foreign trade service products to meet your diverse needs

Learn more about the dynamics and professional knowledge of the foreign trade industry

The holiday season brings a flood of new customers...

MoreChina is one of the world’s largest producers of B...

MoreStepping up your DTF transfer skills isn’t just ab...

MoreDirect-to-Film (DTF) transfers offer a fantastic w...

MoreSelect the most popular foreign trade service products to meet your diverse needs

Explore more content related to foreign trade services

Tel: +86 17706217416

Add: Building L2A, No. 520, Lane 1588, Zhuguang Road, Hongqiao World Center, Qingpu District, Shanghai, China

User Comments

Service Experience Sharing from Real Customers

Michael Chen

Print Shop OwnerThis PET film is a game-changer for our DTF printing. The release is incredibly consistent, and the film's dimensional stability prevents any misalignment during transfers. Our color vibrancy and detail have improved noticeably.

Sarah Johnson

Apparel DesignerAs a designer running a small brand, I need reliable materials. This PET film delivers perfect results every time. No curling, no residue left on the film, and the transfers onto dark fabrics are exceptionally opaque and soft. Highly recommended!

David Rodriguez

Production ManagerExcellent clarity and thickness. It feeds through our DTF printers without jamming, which has significantly reduced our downtime. The only minor point is that we wish it came in a more eco-friendly bulk packaging. The product itself is top-tier.

Emily Watson

DTF Printing SpecialistI've tested many PET films, and this one stands out for its superior ink adhesion and quick drying time. It allows for high-speed production without sacrificing quality. The finished transfers are durable and wash-resistant. A must-have for serious DTF operations.