The Pros and Cons of DTF film printing: A Comprehensive Guide

In the dynamic world of custom apparel printing, b...

More

Finding the best dtf film for epson 8550 users involves a key decision. Hot peel film accelerates production speed and gives garments a softer feel. Cold peel film offers a different set of advantages for specific applications.

It provides superior durability and is unmatched for printing highly detailed, vibrant designs.

Hot peel film helps you print faster. It makes designs feel soft and look matte. Use it for simple designs and large orders.

Cold peel film makes designs last longer. It shows fine details well and gives a glossy finish. Use it for complex art or items needing many washes.

Always test your film and heat press settings. Store DTF film properly. Use single-sided film for the Epson 8550 printer.

The choice between hot peel and cold peel film directly impacts a print shop's workflow, product quality, and overall efficiency. Understanding their fundamental differences is crucial for any DTF printer. These films may look similar, but they behave very differently during and after the heat press process.

The most obvious difference lies in the name itself: when the user peels the film from the garment. This distinction stems from the chemical composition of the film's release layer.

Hot Peel Film: This film is designed for immediate removal. Users peel the film away just seconds after the heat press opens, while the garment and transfer are still hot. The heat activates the release layer, allowing it to detach cleanly from the ink. This process significantly speeds up production.

Cold Peel Film: This film requires a cooling period. The garment must return to room temperature before the user can peel the film. Attempting to peel it while hot will ruin the transfer. The adhesive needs time to fully set and bond with the fabric fibers for a successful release.

The release mechanism at a microscopic level explains this behavior. The base components are similar, but the release layer's reaction to heat is entirely different.

| Feature | Hot Peel DTF Film | Cold Peel DTF Film |

|---|---|---|

| Release Layer | Becomes more adhesive when hot. | Stays inert when heated. |

| Bond to Underlayer | Bonds tightly to the transfer medium when hot. | Maintains a lower bond to the underlayer when hot. |

| Release Mechanism | Requires heat for strong adhesion and subsequent release. | Maintains consistent, lower adhesion for cold release. |

The peeling method directly influences the final texture and appearance of the design on the garment. Each film type creates a distinct finish.

Hot peel film tends to press the ink deeper into the fabric's weave. This integration results in a softer "hand," meaning the design feels less like a plastic layer and more like part of the shirt. It typically produces a modern, non-reflective matte finish.

Cold peel film, in contrast, allows the ink and adhesive layer to set on top of the fabric. This creates a slightly thicker transfer with a vibrant, glossy finish that makes colors pop. The choice often comes down to the desired aesthetic.

| Feature | Hot Peel Film | Cold Peel Film |

|---|---|---|

| Finish | Matte, more textured look. | Glossy result. |

| Color Effect | Flatter, integrated appearance. | Brighter, shinier finish. |

| Finished Texture | Smoother feel, more integrated design. | More rigid feel, plastic-like texture. |

Durability is a primary concern for custom apparel. Cold peel film generally holds the advantage in this category. The cooling process allows the adhesive to create a stronger, more permanent bond with the fabric fibers. This results in transfers that can withstand more rigorous washing and stretching.

Note: For workwear, athletic apparel, or any item expected to endure frequent laundering, cold peel film is the superior choice for maximizing the life of the print.

While hot peel transfers are still very durable for retail and promotional items, they may show signs of wear, like cracking or peeling, sooner than their cold peel counterparts after many wash cycles. Industry tests confirm that while both are robust, cold peel often has a slight edge in longevity. The best dtf film for epson 8550 users seeking maximum wash resistance is often a premium cold peel variety.

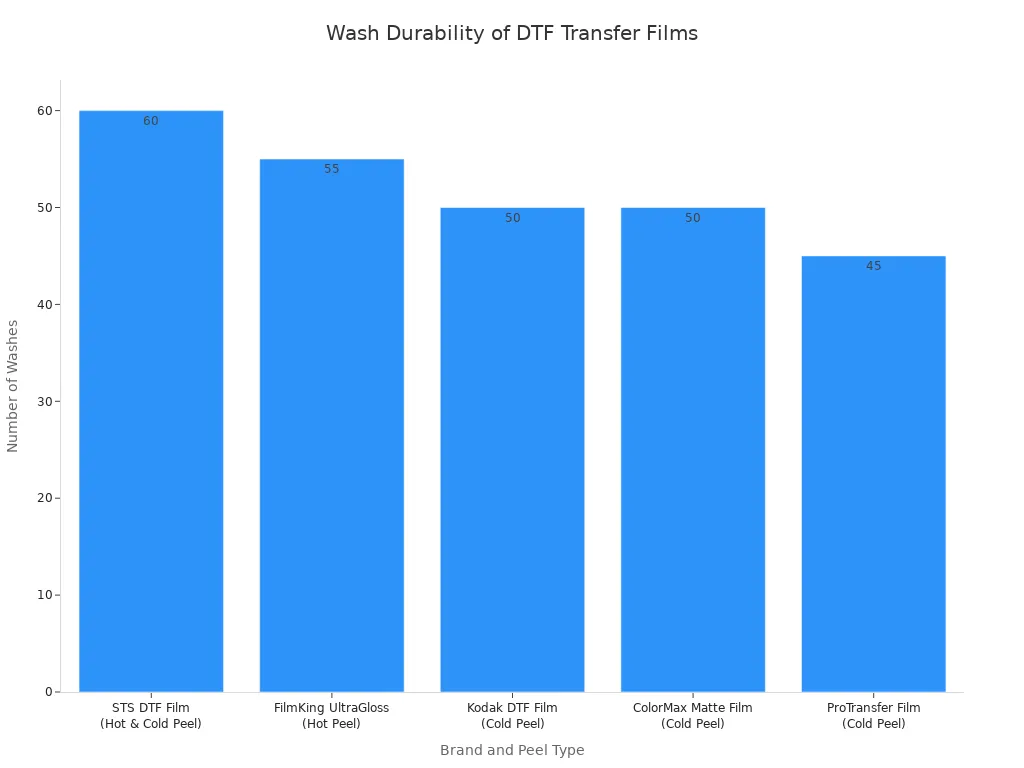

| Brand | Peel Type | Wash Durability |

|---|---|---|

| STS DTF Film | Hot & Cold Peel | 60+ washes |

| FilmKing UltraGloss | Hot Peel | 55+ washes |

| Kodak DTF Film | Cold Peel | 50+ washes |

| ColorMax Matte Film | Cold Peel | 50 washes |

| ProTransfer Film | Cold Peel | 40-50 washes |

The Epson 8550 excels at printing sharp, intricate graphics. The type of DTF film used can either preserve or compromise that detail.

Cold peel film is the undisputed champion for fine lines, small text, and complex patterns. Because the transfer cools completely, the delicate ink elements solidify and bond securely to the garment before the film is removed. This prevents tiny details from lifting or stretching during the peeling process.

Hot peel film can be challenging for highly detailed designs. The immediate peeling action, while the ink is still pliable, can cause small, unsupported parts of the design to pull away or distort. It performs best with bolder graphics, block letters, and less intricate artwork. Finding the best dtf film for epson 8550 projects with complex art means choosing cold peel.

Hot peel DTF film is not just an alternative to cold peel; it is a strategic tool for specific production goals. A print shop operator chooses hot peel film to optimize for speed, achieve a particular feel, and complement certain design styles. Understanding its ideal applications allows Epson 8550 users to maximize their efficiency and product quality.

Speed is the defining advantage of hot peel film. In a high-volume environment, every second counts. The ability to peel the film immediately after the heat press opens transforms the production workflow.

An operator can press a shirt, peel the film, and stack the finished garment in a single, fluid motion. This process eliminates the cooling stage, which is a significant bottleneck when using cold peel film. A shop can complete large orders in a fraction of the time, dramatically increasing its daily throughput. ⏱️

For businesses focused on fulfilling bulk orders for events, uniforms, or promotional campaigns, hot peel film is the industry standard. The time saved translates directly into higher profitability and the capacity to accept more jobs.

The "hand" of a garment refers to the way the design feels to the touch. Hot peel film excels at creating a transfer with a remarkably soft hand. During the immediate peeling process, the still-pliable ink layer integrates more deeply into the fabric's weave. It becomes part of the garment rather than sitting on top of it as a distinct layer.

This results in a print that is flexible, breathable, and comfortable to wear. For retail-quality apparel, fashion brands, and any product where wearer comfort is a top priority, the soft hand produced by hot peel film is a major selling point. The final print feels less like plastic and more like a high-end screen print.

The physical properties of hot peel film make it the perfect match for bold and uncomplicated graphics. The immediate peel, performed while the ink is hot and malleable, works best with designs that have substantial, well-supported shapes.

Consider using hot peel film for the following types of artwork:

Large company logos

Block lettering and bold typography

Solid graphic shapes

Simple, single-color designs

Conversely, the hot peeling action can pose a risk to delicate artwork. Tiny, freestanding text or intricate lines may stretch, warp, or fail to adhere properly when the film is pulled away. For designs that rely on fine detail, cold peel remains the safer and more reliable option.

Aesthetic trends in apparel often favor a non-reflective, understated look. Hot peel film is the go-to choice for achieving a professional matte finish. Unlike the high-gloss appearance of cold peel, a hot peel transfer absorbs light, giving the design a subtle and premium quality.

This finish is highly desirable for fashion-forward brands and customers who prefer a more integrated, less "shiny" look. The film's formulation and the application process are key to creating this effect.

Hot peel film is specifically engineered to produce a matte finish on garments.

The process of pressing the ink into the fabric fibers naturally reduces surface gloss.

The resulting transfer appears flat and non-reflective, blending seamlessly with the texture of the fabric.

For Epson 8550 users aiming to produce contemporary apparel with a sophisticated, retail-ready appearance, hot peel film is the superior choice.

Cold peel DTF film serves a critical role for projects where precision and longevity are paramount. Printers select this film to achieve results that hot peel film cannot deliver. Its unique properties make it the ideal choice for specific, high-value applications.

The Epson 8550 produces stunningly detailed prints. Cold peel film preserves every bit of that detail. The cooling process allows the ink and adhesive to fully harden before the film is removed. This prevents tiny lines, small text, and complex patterns from stretching or lifting during the peel. The transfer remains crisp and true to the original digital file.

Cold peel film creates the strongest possible bond between the transfer and the garment. The adhesive has ample time to cure and anchor itself deep into the fabric fibers. This results in a print with exceptional wash and stretch resistance. 🛡️

For workwear, athletic jerseys, or any item requiring maximum longevity, cold peel film is the professional standard. The finished product can withstand repeated, harsh laundering cycles.

The primary trade-off for cold peel film is speed. The required cooling period adds minutes to each press. This makes it less suitable for high-volume, rapid-turnaround jobs. However, for custom one-offs, premium retail pieces, or any project where quality outweighs production speed, the wait is a necessary step for a superior outcome.

Cold peel film delivers a distinct visual effect. The transfer sits slightly on top of the fabric, creating a smooth, glossy finish that makes colors appear brighter and more saturated. This vibrant, almost plastic-like appearance is perfect for designs that need to pop with intense color. ✨ It gives graphics a bold, eye-catching quality that a matte finish cannot replicate.

Identifying the best dtf film for epson 8550 printers goes beyond the hot versus cold peel debate. Achieving consistent, professional results depends on a disciplined workflow and adherence to best practices. The following tips will help users optimize their process for any film they choose.

Before starting a large production run, operators should always perform a test press. Every combination of film, ink, powder, and fabric can yield slightly different results. A small test swatch allows a printer to verify color accuracy, adhesion, and the feel of the transfer. This simple step prevents wasted materials and ensures the final product meets quality standards.

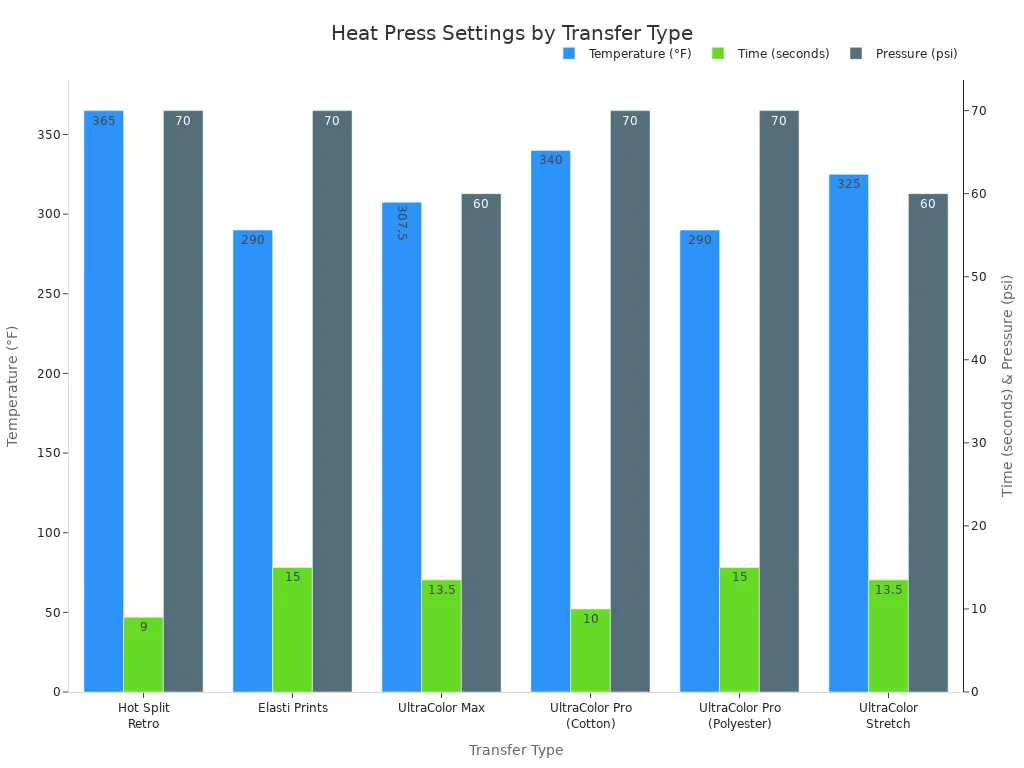

There is no universal setting for DTF transfers. The ideal temperature, time, and pressure depend heavily on the film type and the garment's fabric content. Using incorrect settings can lead to poor adhesion or scorched fabric. Printers should start with the manufacturer's recommendations and adjust as needed.

Tip: Polyester and synthetic blends require lower temperatures than 100% cotton to prevent damage to the fabric fibers.

| Fabric Type | Temperature | Time | Pressure | Peel Type |

|---|---|---|---|---|

| Cotton | 315°F (157°C) | 15 seconds | Medium to firm | Cold peel recommended |

| Polyester & Blends | 290°F – 300°F (143°C – 150°C) | 12 – 15 seconds | Light to medium | Hot peel recommended |

Calibrating these variables is essential to finding the best dtf film for epson 8550 applications.

DTF film is sensitive to environmental conditions. Improper storage can ruin an entire roll, leading to significant financial loss. To maintain film integrity, users must protect it from moisture, heat, and light.

Consequences of poor storage include:

Premature peeling caused by moisture absorption.

Color fading from exposure to direct sunlight.

Compromised adhesion and a diminished shelf life.

Curling or creasing if the film is not stored flat.

Store film in a cool, dry place, preferably in its original sealed packaging.

For desktop printers like the Epson 8550, using single-sided film is critical. Double-sided films have a coating on both sides, which can flake off and contaminate the printer's rollers. This contamination leads to misfeeds, jams, and poor print quality. Sticking to single-sided film is a simple way to protect the equipment and ensure smooth operation. This choice is a key part of selecting the best dtf film for epson 8550 users.

Finding the best dtf film for epson 8550 depends entirely on project needs. Hot peel film prioritizes speed and a soft feel for general jobs. Cold peel film delivers maximum detail and wash resistance for premium work. Stocking various types, from standard matte to specialty films, ensures a shop is prepared for any customer request. Always test your materials to perfect the final result.

Printers should avoid using hot peel film for intricate artwork. The immediate peeling action can stretch or damage fine lines. Cold peel film provides superior results for detailed graphics.

Improper peeling often results from incorrect heat press settings or peeling too slowly. Operators must ensure the temperature is accurate and peel the film quickly and confidently. ⏱️

Neither film is universally better. The best choice depends on the project.

Cold peel excels in durability and detail. Hot peel offers speed and a softer feel for high-volume jobs.

Select the most popular foreign trade service products to meet your diverse needs

Learn more about the dynamics and professional knowledge of the foreign trade industry

In the dynamic world of custom apparel printing, b...

MoreChina is one of the world’s largest producers of B...

MoreFor small print shops and creators, 2026 is shapin...

MoreBOPP Film, or Biaxially Oriented Polypropylene Fil...

MoreSelect the most popular foreign trade service products to meet your diverse needs

Explore more content related to foreign trade services

Tel: +86 17706217416

Add: Building L2A, No. 520, Lane 1588, Zhuguang Road, Hongqiao World Center, Qingpu District, Shanghai, China

User Comments

Service Experience Sharing from Real Customers

James Wilson

Print Shop OwnerAfter testing several brands, this DTF film is by far the best for my Epson 8550. The transfer is incredibly crisp, and the white layer is perfectly opaque even on dark fabrics. My production speed has increased thanks to its reliable performance.

Sarah Chen

Apparel DesignerAs a small business owner, consistency is key. This film delivers flawless results every time on my Epson 8550. No cracking, excellent color vibrancy, and the adhesive sticks perfectly after curing. It has become my go-to film for all custom orders.

Michael Rodriguez

Production ManagerWe run high-volume orders and needed a durable film. This one works exceptionally well with the Epson 8550. Minimal film curling, excellent ink adhesion, and very few misprints. The slight premium in cost is worth the reliability and reduced waste.

Lisa Thompson

DTF SpecialistI've specialized in DTF printing for 3 years. This film is optimized perfectly for the Epson 8550's printhead. The detail retention on fine text and complex graphics is unmatched. It's the best film on the market for achieving professional, retail-quality prints.